Test Systems

Long track record of turnkey solutions for the wind industry

Long track record of turnkey solutions for the wind industry

Increase competitiveness

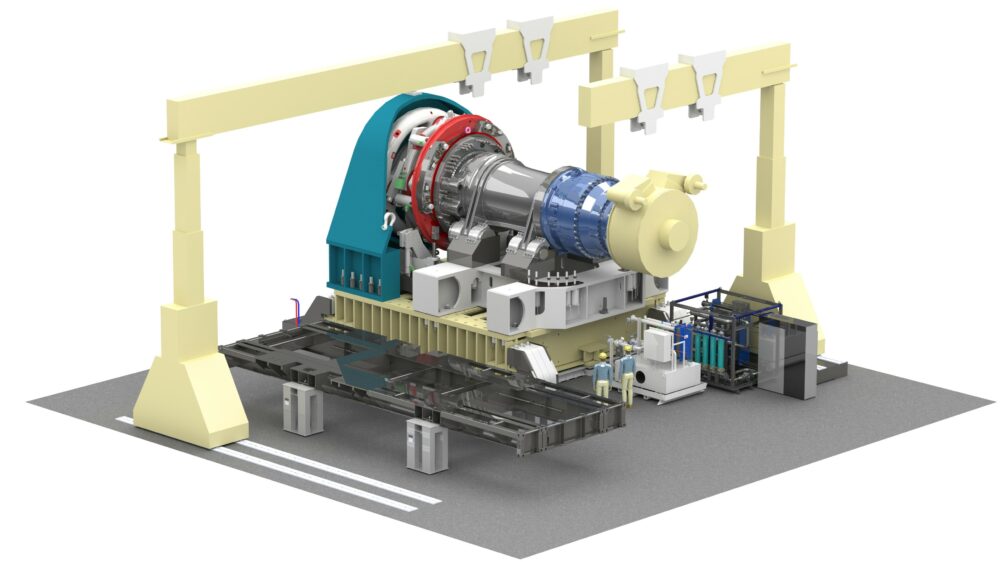

R&D Test Systems has obtained unique experience and system insight by developing demanding, large-scale test systems for the wind industry. Our extensive track record enables us to help you select the most suitable type of test for your device under test (DUT), from testing of major components and technologies to complete nacelles.

As we work with both the technology development and prototype testing, we understand the whole development process of a new wind turbine. This gives us an edge and makes us able to supply test systems that are more innovative, cost-efficient, and sustainable.

Our test benches are delivered to the largest OEMs and tier-one wind industry suppliers, including Vestas, ZF, Flender, and LORC, making us the number-one partner of large-scale test systems for the wind industry.

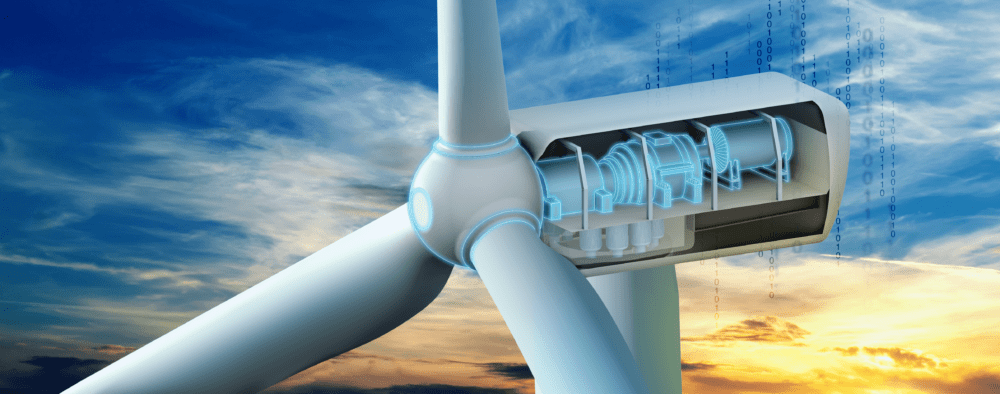

Testing can save millions

As the next generation of offshore wind turbines set to become bigger, more powerful, and have shorter development cycles, testing of the wind turbine's value chain becomes essential. Testing will allow manufacturers to evaluate the new products under realistic conditions, thus estimating lifespan and maintenance requirements. This process can save millions of euros in warranty claims and downtime and, at the same time, add reliability.

What do you need for your test facilities?

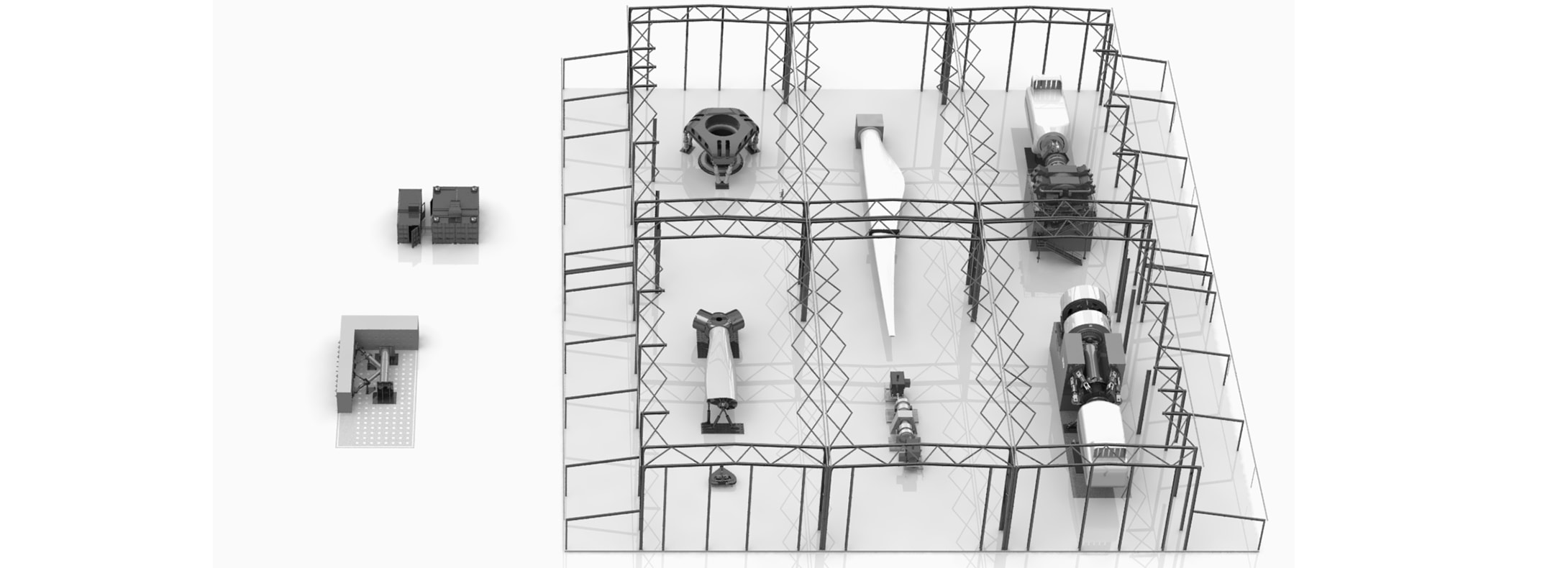

Our tailor-made test systems are customized to meet our customer's requirements and needs.

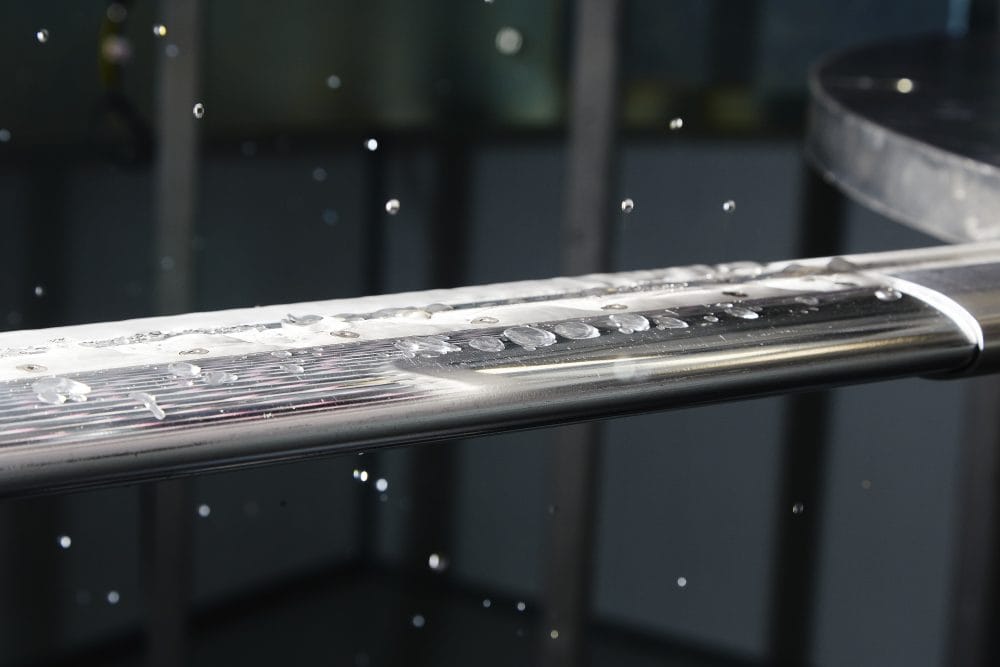

Proven technology for the testing of rain erosion of wind turbine blades. The system fulfills DNV's Recommended Practice (DNV-RP-0171).

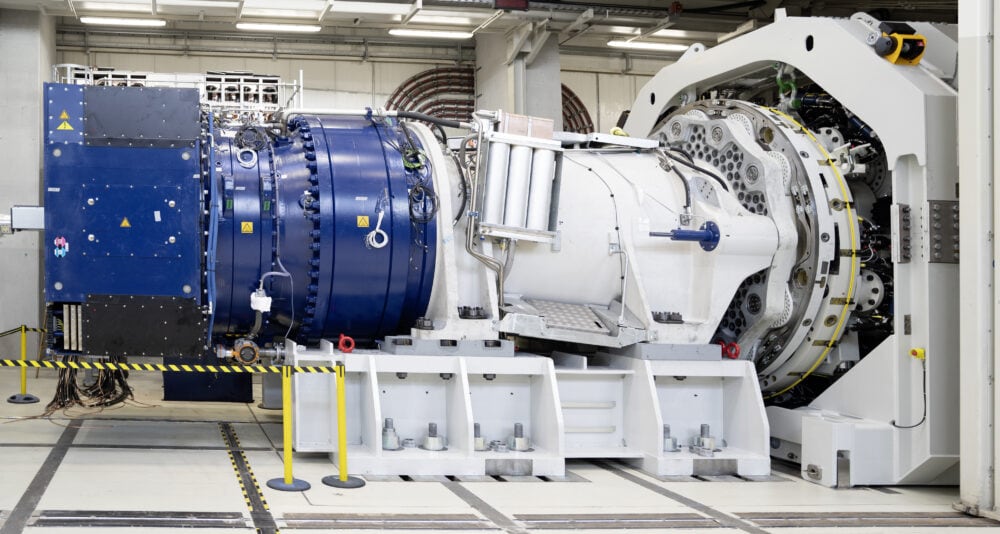

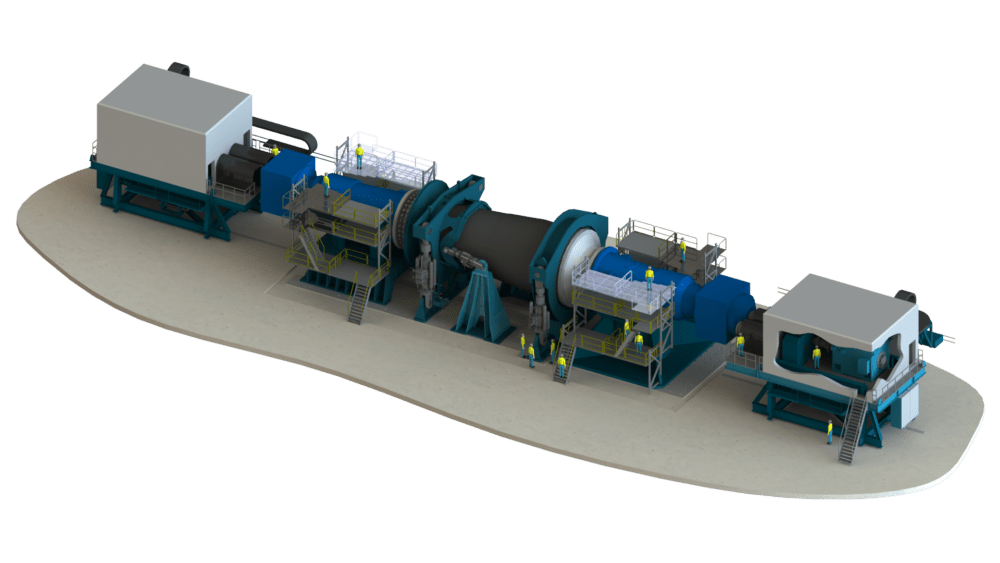

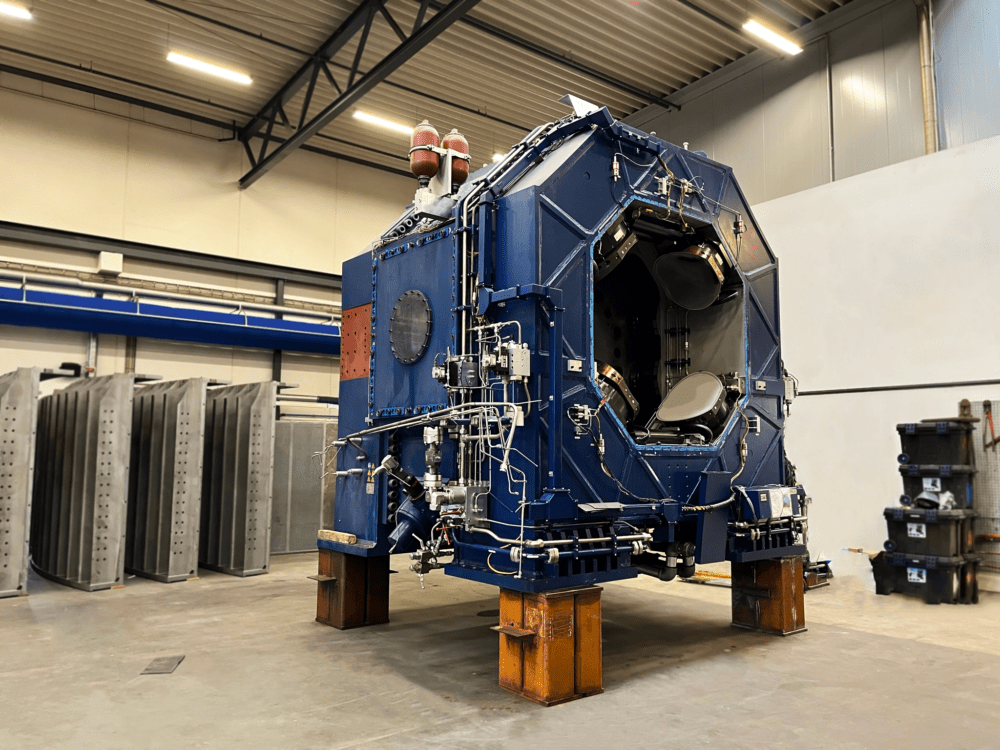

Multi-purpose test bench for the testing of larger mechanical subsystems or components.

Tailor-made systems for complete pitch systems or pitch bearings.

Tailor-made test system for large-scale bearings.

Testing of yaw ring segments.

Functional, end-of-line or HALT testing of gearboxes.

Highly accelerated lifetime testing of complete nacelles or drive trains.

Function testing of complete nacelles, including the hub.

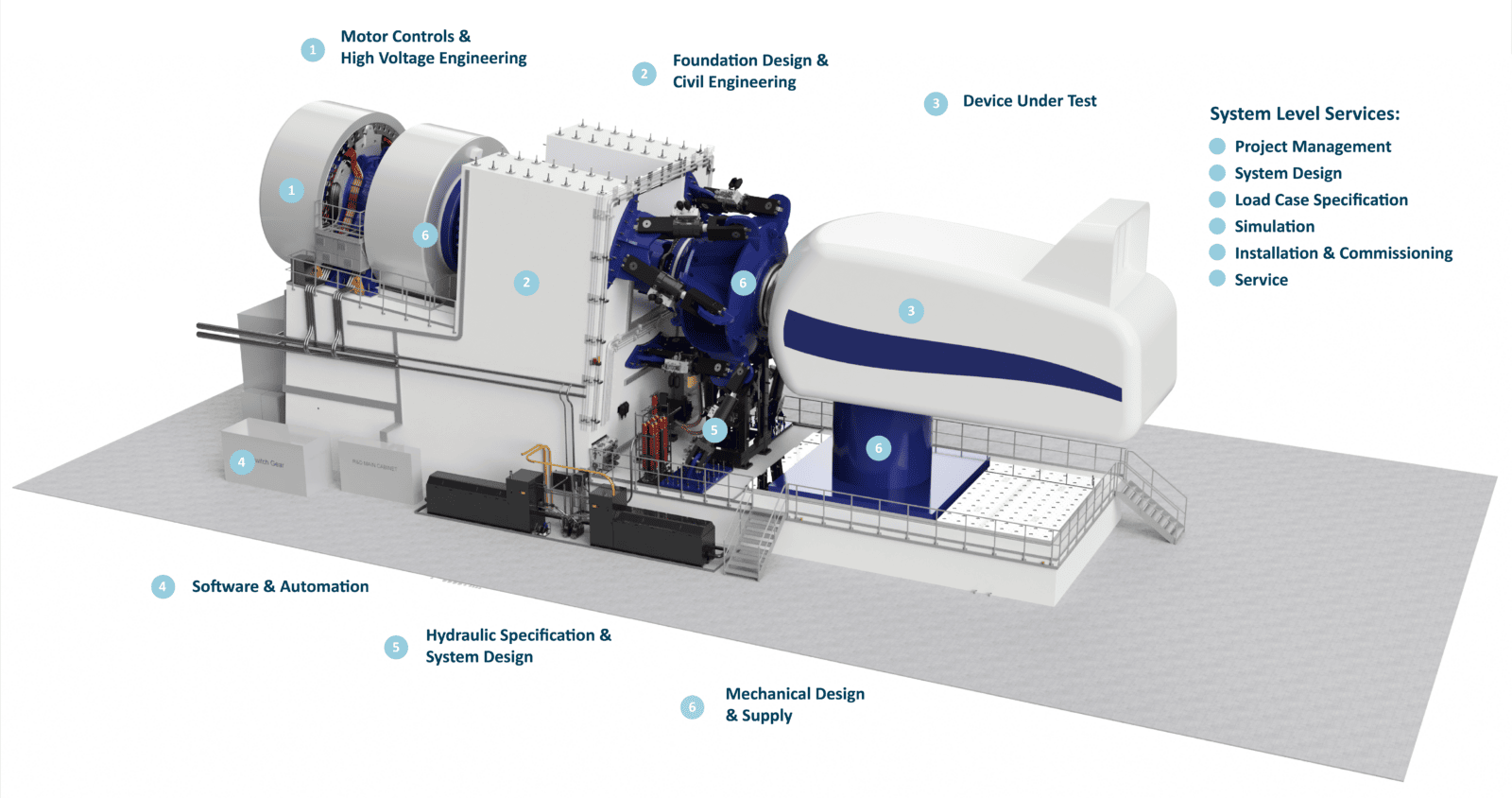

System-wide range of specialists

Our rich palette of in-house specialized competencies ensures efficient project execution and world-class test systems for our customers.

Learn more about our competences

Learn how we use dynamic simulations to create value for our customers by minimizing downtime on the test benches and minimizing commissioning time on site

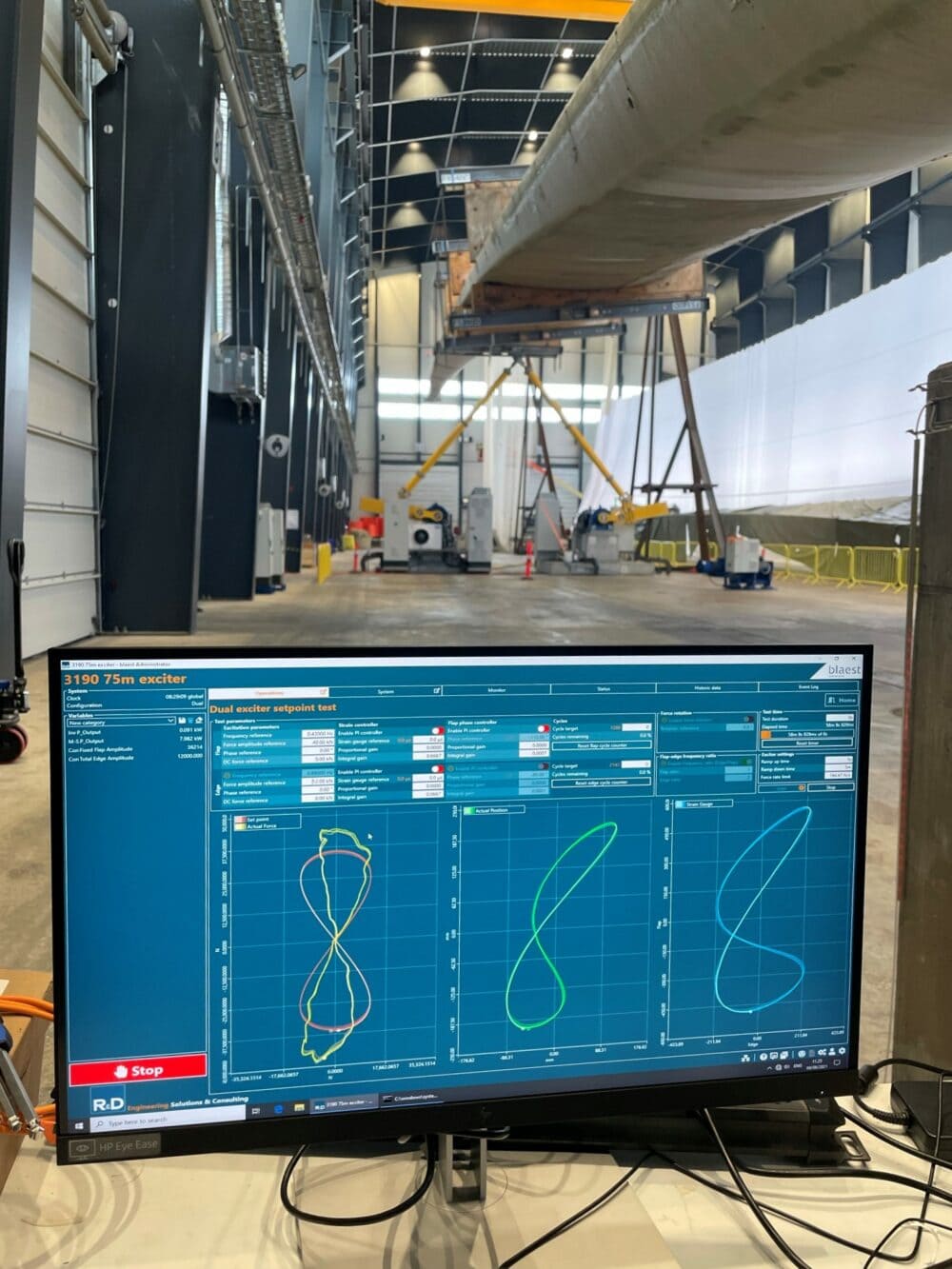

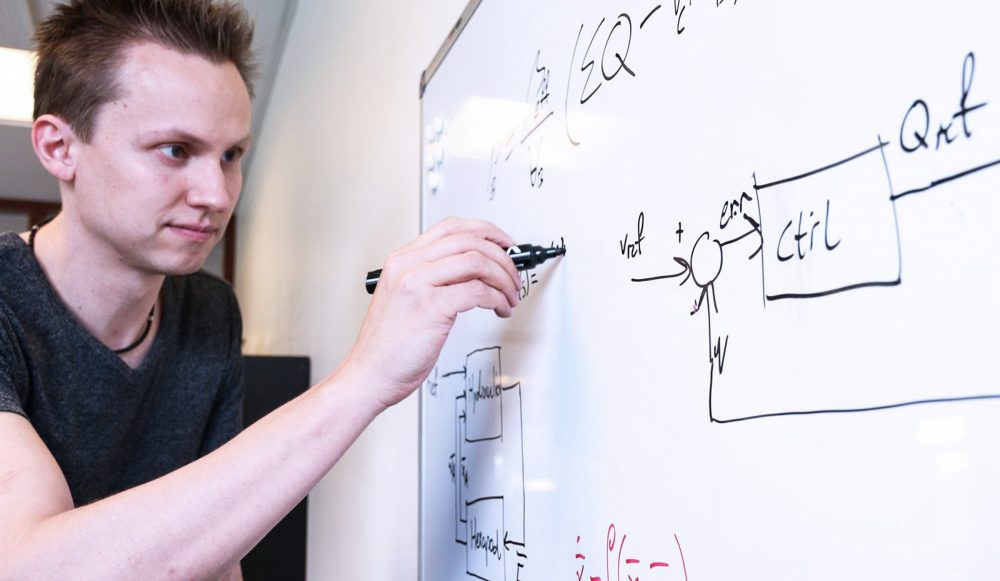

R&D Test Systems specializes in dynamic simulations for test benches. Our expertise lies in movements, encompassing both linear and rotary dynamics. Unlike static strength simulations conducted by finite elements, our focus on dynamic simulations enables us to determine the motions and behaviors of dynamic systems. We are developing and building our own tailored control software for our test bench. The dynamic simulation models empower us to validate and pre-test novel functions and algorithms seamlessly before deployment on the physical plant.

At R&D Test Systems, we have spent the last 10-15 years developing a model and sub-model library. We utilize these sub-models like LEGO bricks to construct large complex models for new test benches. By doing dynamic simulations, we create value for our customers by minimizing downtime on the test benches and commissioning time on site. In prior projects, we successfully utilized the dynamic simulation model to start up the commissioning phase of the test bench before the hardware was built.

Watch our colleague Kristian Kongerslev explain dynamic simulation.

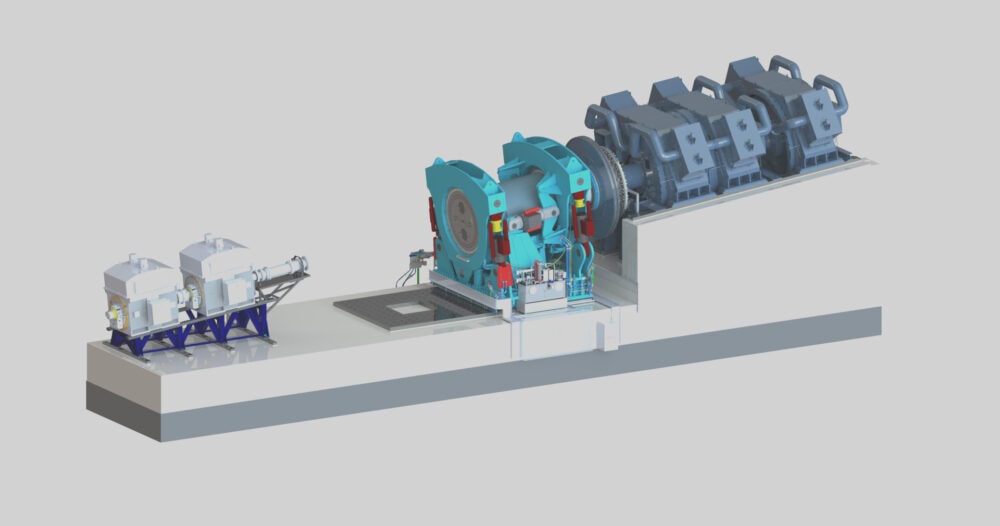

Learn how we optimize and engineer a test system with a Test Load Unit (TLU)

When designing a test bench with a Test Load Unit (TLU), we need to achieve some predefined loads. In order to achieve this, we use kinematic models to calculate the loads that need to be applied to the device that is being tested, also called the Device Under Test (DUT).

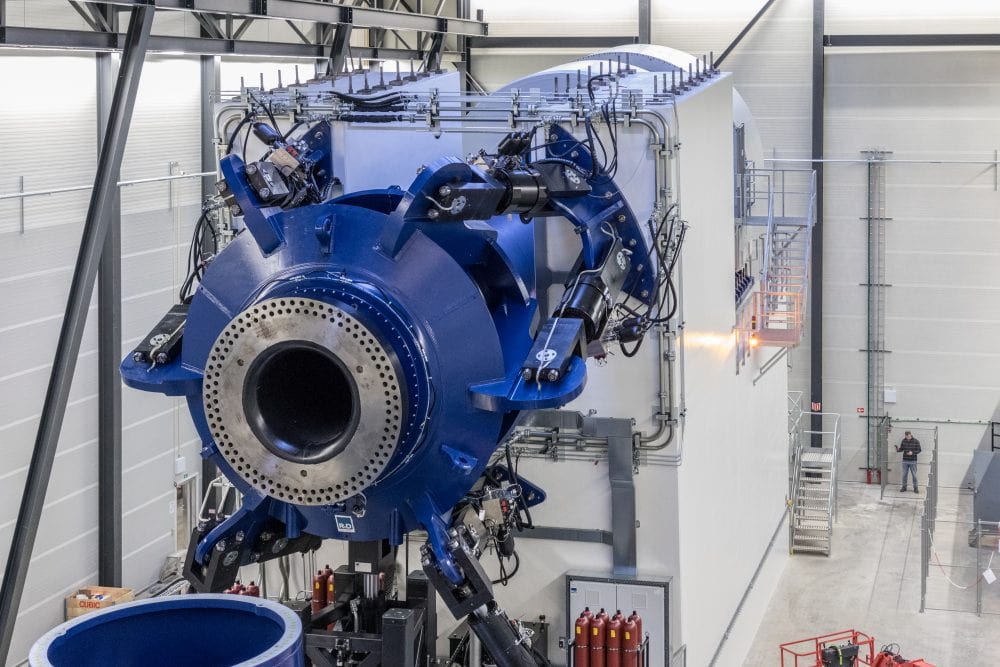

The TLU is a parallel robot, meaning that a bunch of actuators act in parallel with one another to apply loads to a DUT. We use kinematic and dynamic models to design the TLU through simulation of various predefined load cases. The purpose of these models is to relate the movements and loads of the DUT to the movements or forces of the actuators in the TLU. For example, if a requirement states that the DTU should be exposed to a bending moment of 50 MNm, the kinematic models will predict how the TLU should act to achieve this.

Not only are the kinematic models used in the design phase of the TLU, but the same models are the backbone of the TLU’s control system. It is a unique task to make the complex kinematic models useful in the control of the test bench. However, R&D Test Systems have succeeded in creating a user-friendly HMI that can do this. Through this interface, we can align the TLU with the device under test (DUT) and control the loads applied to the DUT intuitively.

Our TLU plays a crucial role in validating wind turbine main- and subcomponents efficiently. It enables manufacturers to test their components within a short timeframe, demonstrating their ability to withstand 25 years at sea in just two to three months.

Watch our colleagues Frederik Thomsen & Simon Christensen explain the TLU.

Learn how we use advanced numerical calculations to optimize engineering projects.

R&D Test Systems supplies advanced numerical calculations and Finite Element Analysis (FEA) to analyze the large structures in our test benches. We have a standard software that we use for making stress and displacement evaluations. When we want to do some more deep-dive investigations of the welds and the bolts, we use our specialized tools to investigate and figure out: what is the utilization, what is the damage, and how much are these specialized components able to withstand.

When building a test bench, we create detailed CAD models and designs that need to withstand the loads from the test bench. One of the challenges of designing the structures and the components is to figure out how each part copes with the loads as well as how the parts affect each other. To overcome this challenge, we combine the designs and loads in software that evaluates if the design is sufficient, too heavy, too light, or just perfect. Integrating these methods into a comprehensive computational model helps us understand the interplay between different parts, which is essential for meeting the system requirements.

Depending on the design model's size and complexity, evaluations may take anything from minutes to weeks. In prior projects, we successfully investigated a component’s strength and optimized its stiffness, achieving a maintenance-free design that met strict requirements.

Watch Thomas Møller Christiansen explain how he works with finite element analysis (FEA).

How can we help you?