Test Systems

Wind turbine blade testing

Wind turbine blade testing

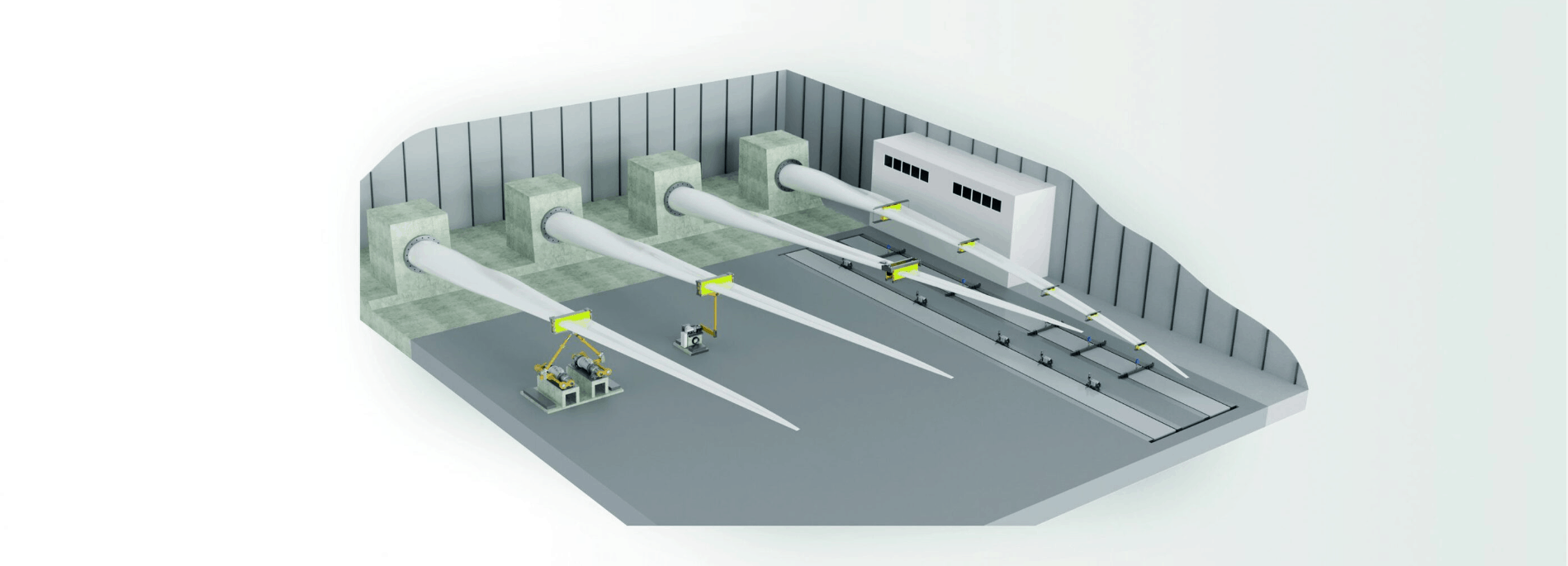

Full-scope supplier of wind turbine blade test systems

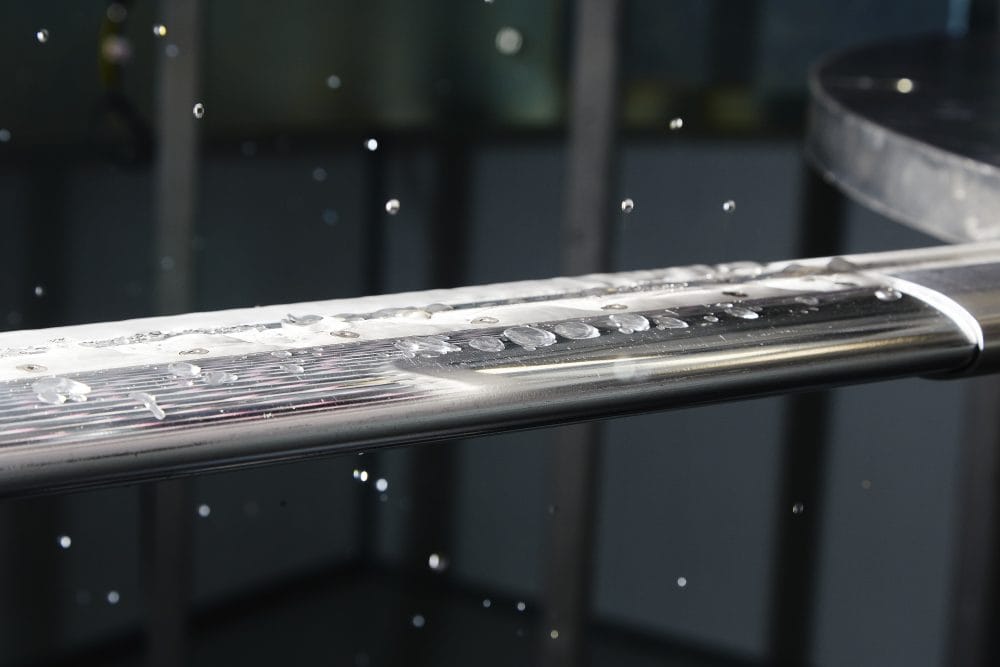

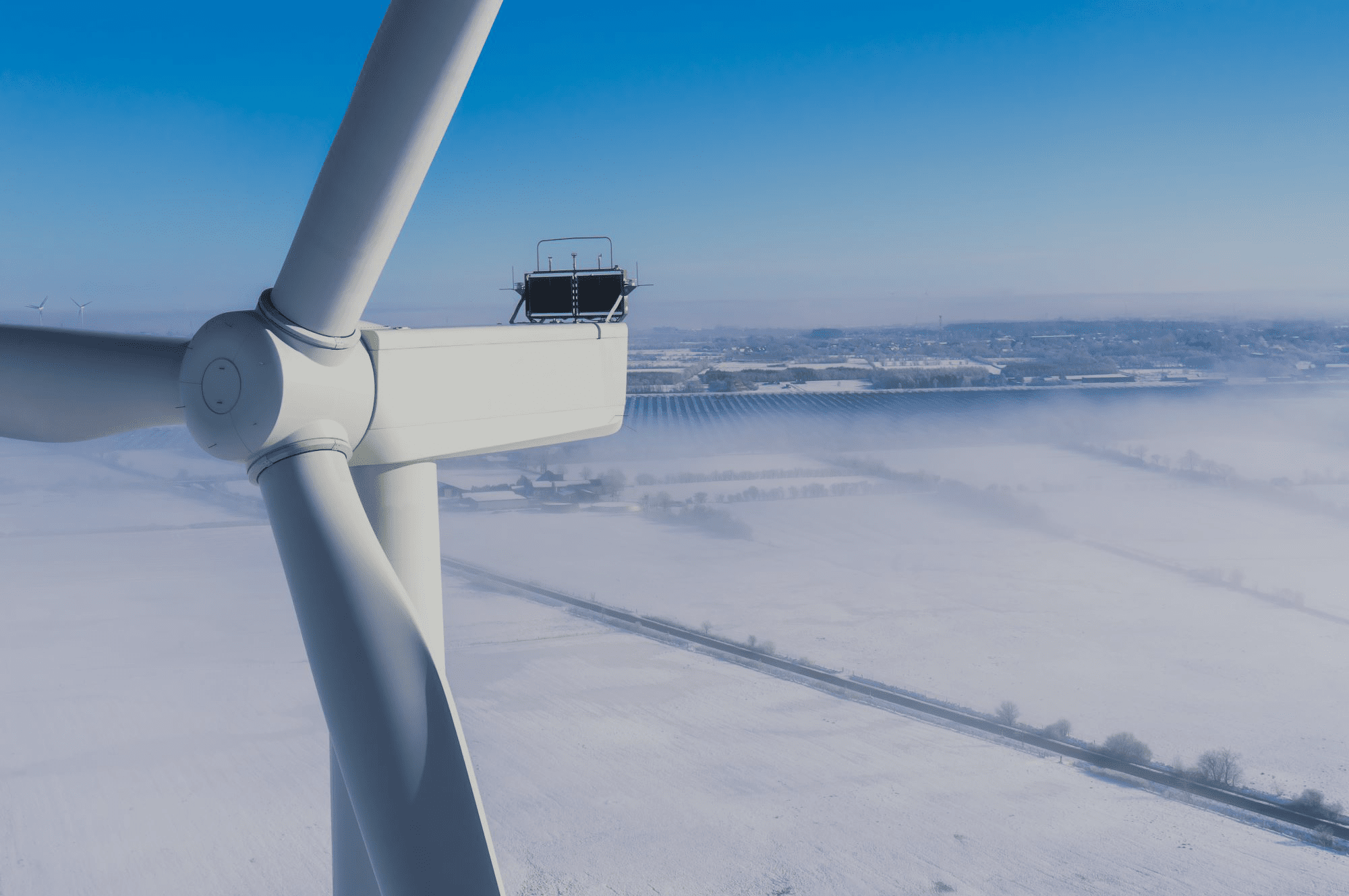

Rotor blades are subjected to both aerodynamic loads and inertial loads, which cause them to bend and twist in different directions. As blade design continues to increase in dimension and proportion, the requirements of your test equipment increase as well.

With our unique experience within test systems for the wind industry, you get advanced test solutions for your rotor blade; from a standard test system to a tailor-made turnkey test system.

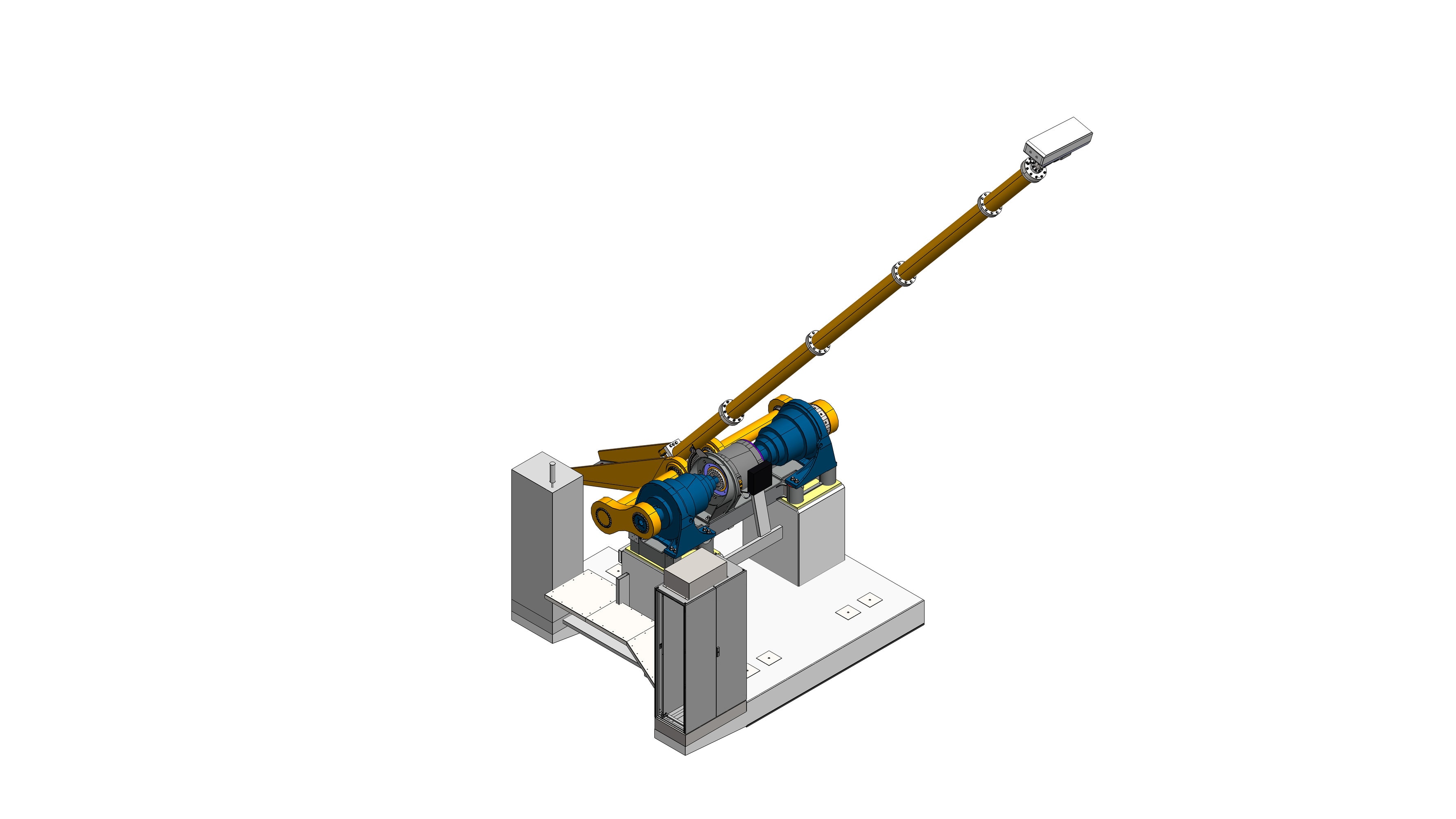

Blade fatigue exciter

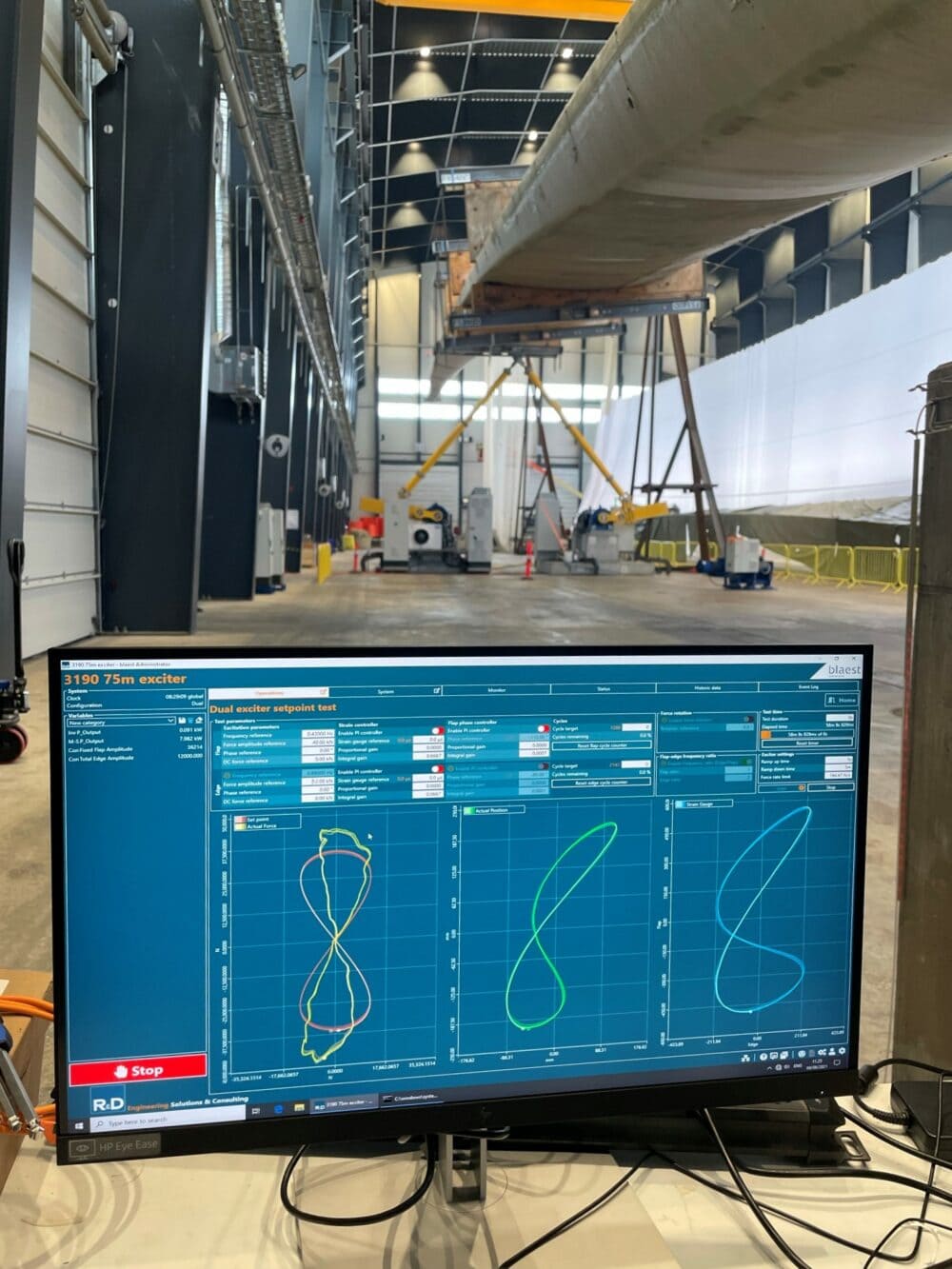

The testing solutions from R&D Test Systems enable you to verify your rotor blades according to the international standard IEC 61400-23. It is modularized test system that can simultaneously apply flap- and edgewise loads. The test system can be used as a single unit to test flapwise or edgewise fatigue. Or, two units can be used in combination to achieve dual-axis functionality or extremely large loads in one direction.

We have developed a full-scale multi-axis fatigue blade test system that can test blades up tp 130 meters. So far, the test system has been sold to Blaest in Denmark, WTTC in the US, and NWETC in China.

Specifications:

- Blade input force: 240 kN

- Excitation power: 440 kW

- Excitation frequency: 0.15 - 1 Hz

- Vertical displacement: 3800 mm

- Handles up to 130-meter blades

- Backlash-free design ensures precise and smooth force application

- Low noise operating

Click to see our wind turbine blade test equipment

We are well-versed and highly experienced in developing foundations for large-scale test systems. We are able to develop and deliver customized foundation designs which fit the requirements of the test site.

The Dual Axis Electrical Blade Exciter for full-scale multi-axis fatigue blade testing.

The setup consists of an electrical ground-based exciter that applies flap and edgewise loads simultaneously. This setup ensures not only that the test system applies test loads equivalent to the loads experience under operation on the turbine but also reduces the overall duration for testing of the blades.

The test system can be developed and delivered as a standard setup or customised to fit your requirements.

The fatigue test setup for accelerated lifetime testing consists of the Single Axis Flap Exciter and/or the Single Axis Edge Exciter. Both the Single Axis Flap Exciter and the Single Axis Edge Exciter can be delivered as a rotating mass exciter

and/or a ground-based exciter.

The Single Axis Flap Exciter and the Single Axis Edge Exciter can be developed and delivered as a standard setup or customised to fit your requirements.

An advanced control system is included in our standard test equipment, which is widely used by our customers worldwide. We are able to integrate either a standard control system in the test equipment or develop a customised control system according to your requirements.

R&D Test Systems also offers a data acquisition system for collection of data from your blade testing.

The static test equipment is designed to apply the needed extreme loads in all directions, i.e. towards the leading edge, trailing edge, suction side and pressure side in order to validate the blade design.

The static test system can be developed and delivered as a standard setup or customised to fit your requirements.

R&D Test Systems: Blade fatigue exciter

See the dual-axis blade exciter in action, performing in flap-, edge- and chaotic mode for fatigue blade testing.

How can we help you?

For further information, please contact us