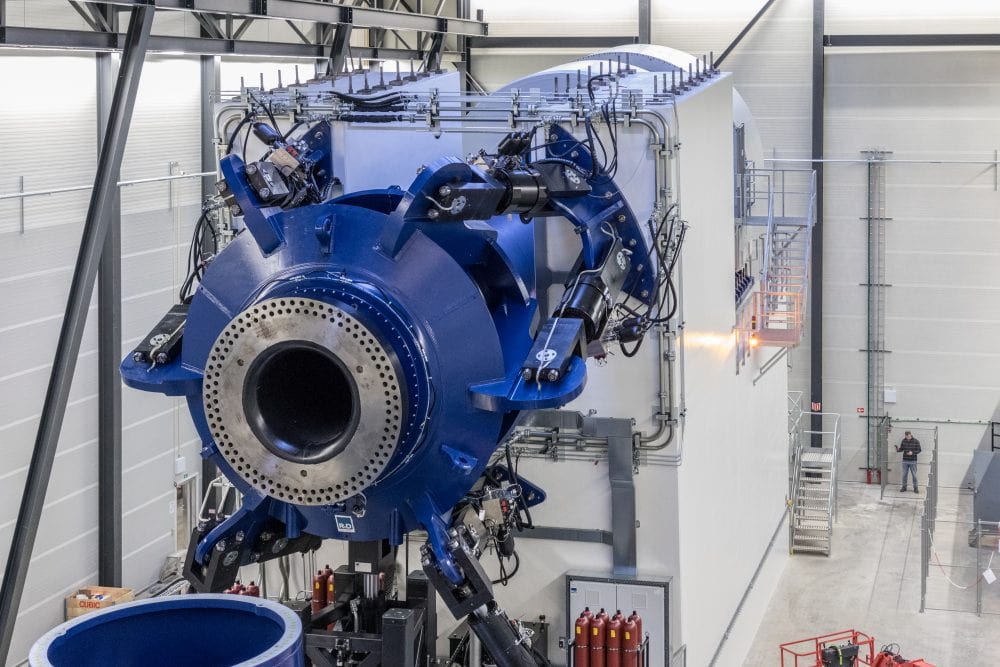

Test Systems

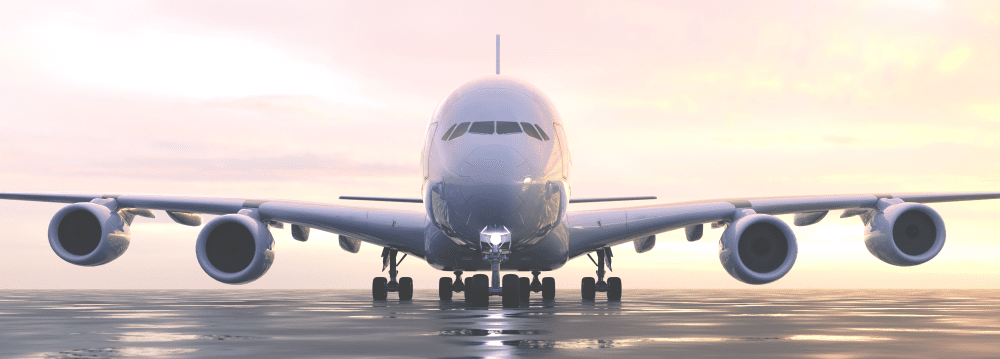

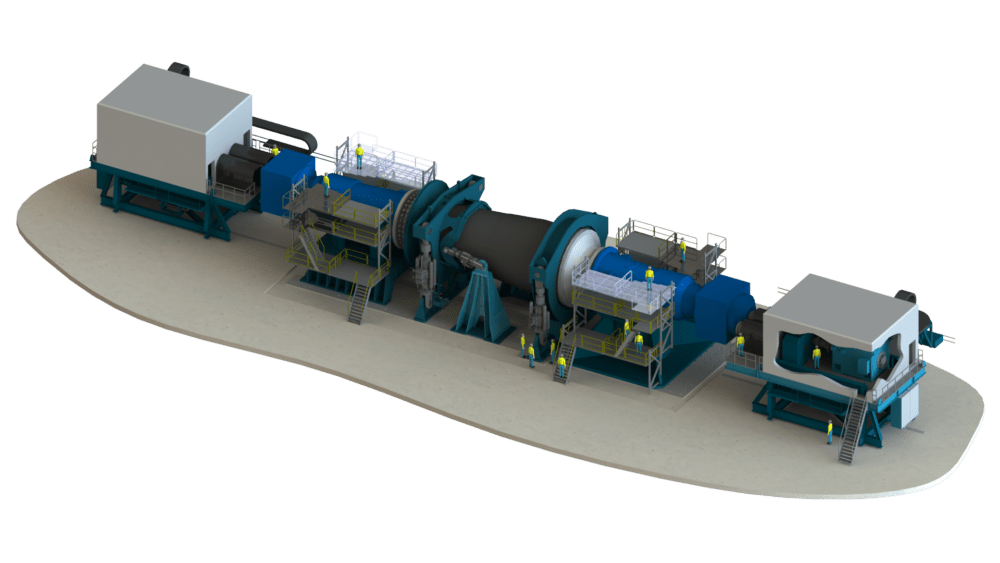

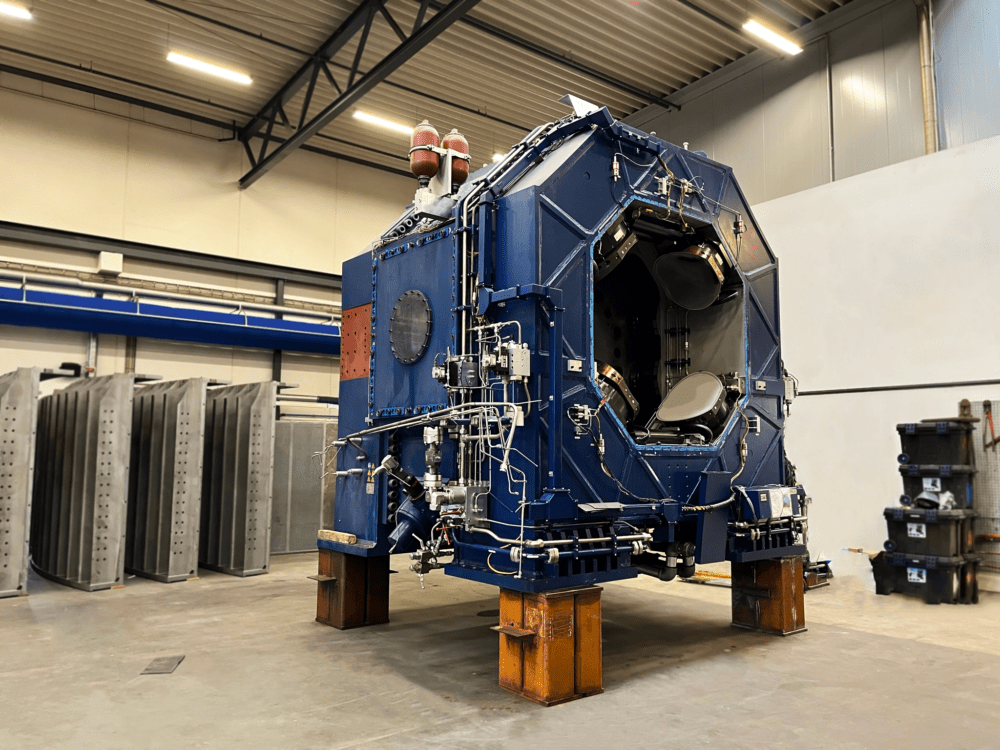

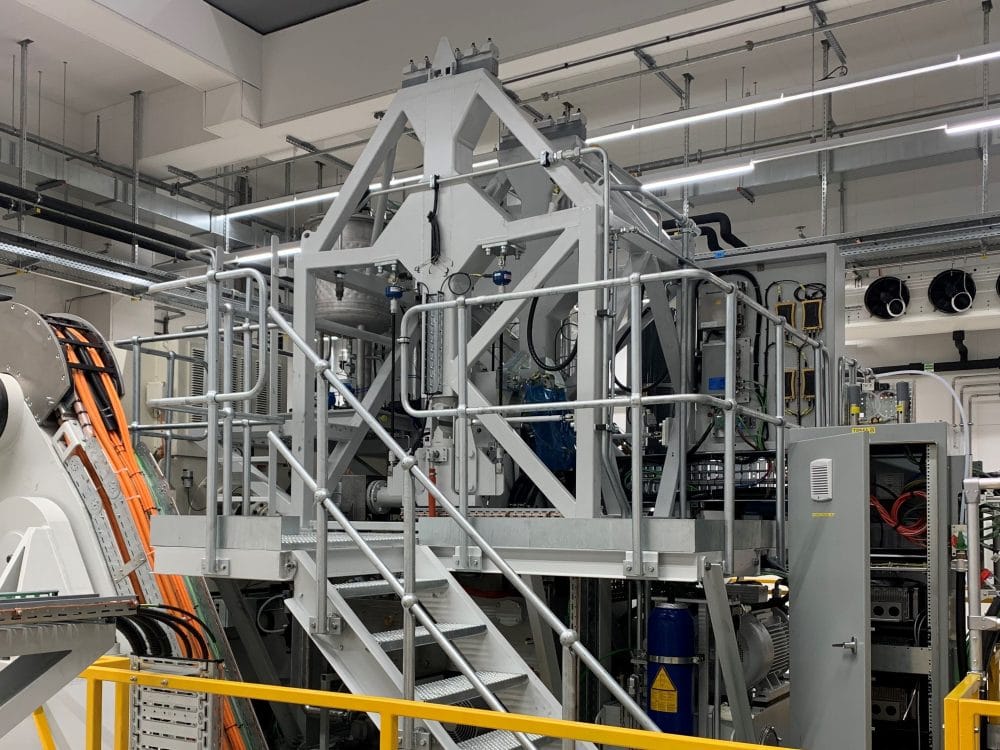

Large-scale and Sustainable Solutions

Large-scale and Sustainable Solutions

Scroll down

01 About

02 Industries

03 Cooperation

04 Insights

05 Contact

How can we help you?

Contact persons

Send us a message