Test Systems

Aerospace testing

Test Systems for the aerospace industry

Optimized and improved test systems

Aerospace testing

Test Systems for the aerospace industry

Optimized and improved test systems

Click to find your new aerospace test system

R&D Test Systems delivers tailor-made and standard test systems that fit your requirements. Below you can click to find an overview of some of the areas.

Aircraft engines require a wide range of different tests, both on system-level and component level.

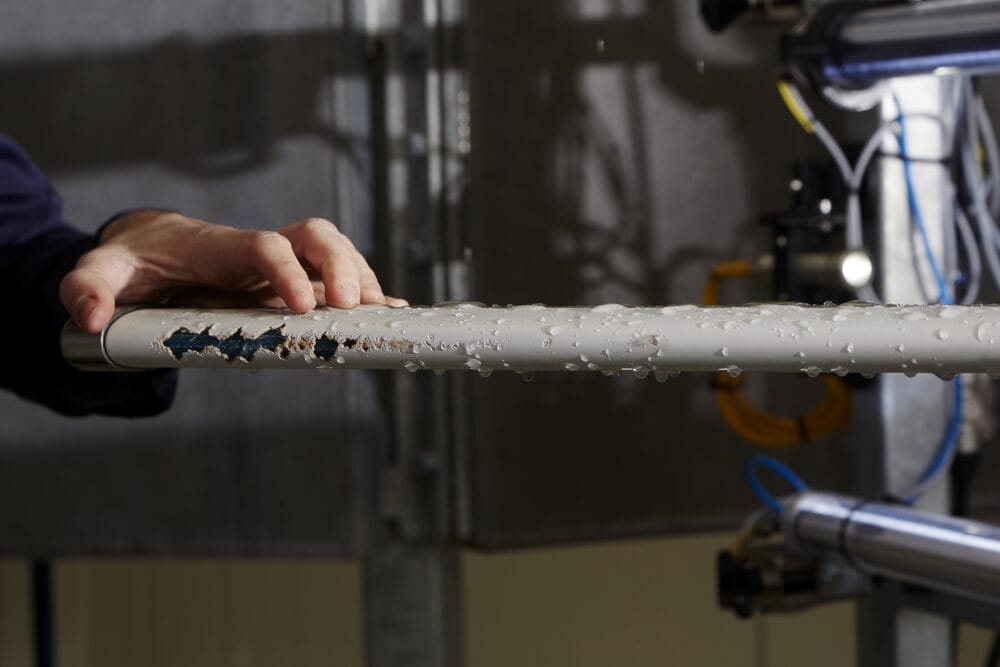

The test rig can simulate rain and particle erosion.

The test setup is based on a 3-bladed helicopter principle that ensures conditions similar to real flight conditions in harsh weather.

The test rig can simulate the effects of take-off, climb, descent, landing, or banking.

The Iron Bird setup enables testing of the flight control and mechanical systems, including landing gear, brakes, and hydraulics.

A static and fatigue test designed to ensure that the landing gear can withstand worst-case scenarios and avoid failure during the aircraft's expected life-cycle.

Testing of different rotating components, for example, gearboxes for aircraft engines.

Study and/or simulation can be used during the development and detailed design of new driveline components to identify critical speeds and delineate keep-out zones.

- Update of existing test rigs

- Engine and transport dollies

- Aircraft jack proof load tester

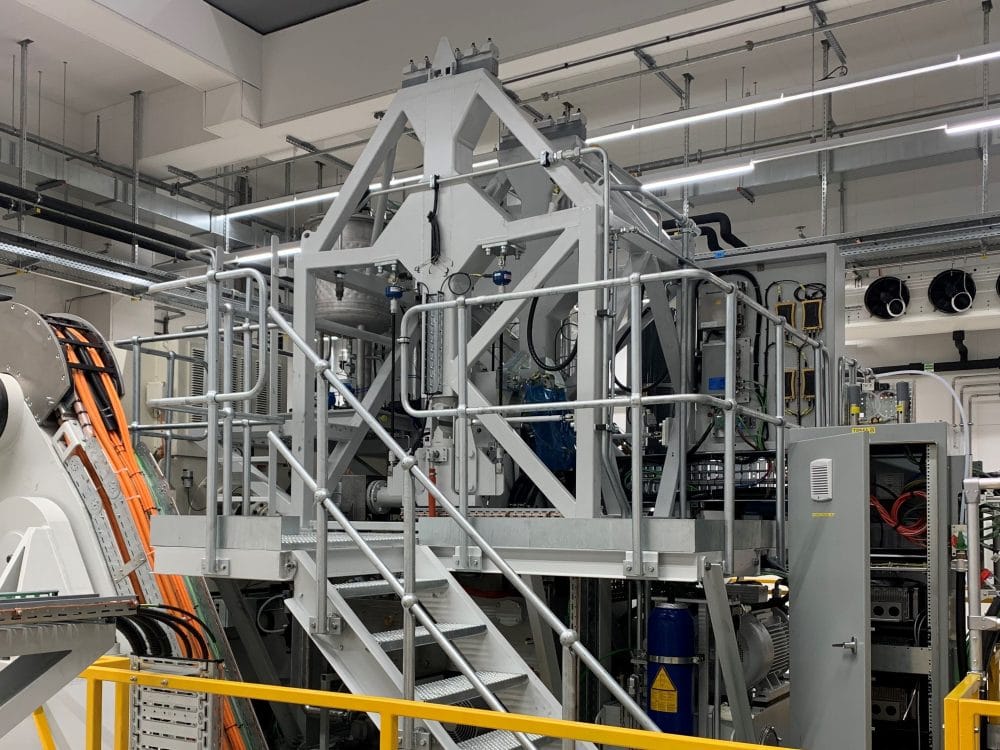

Aerospace gearbox test rig for Rolls-Royce

We have done it before. R&D Test Systems delivered a test rig for one of the world's most powerful aerospace gearboxes to Rolls-Royce.

During the process, R&D Test Systems operated as project managers and managed the mechanical design, drive actuation systems, construction, documentation, and installation, which lead to a solution that fulfilled Rolls-Royce's needs and requirements – a test rig robust enough to withstand the future test scenarios.

How can we help you?