Case study

R&D Test Systems is developing the world’s largest HALT XL test bench for LORC

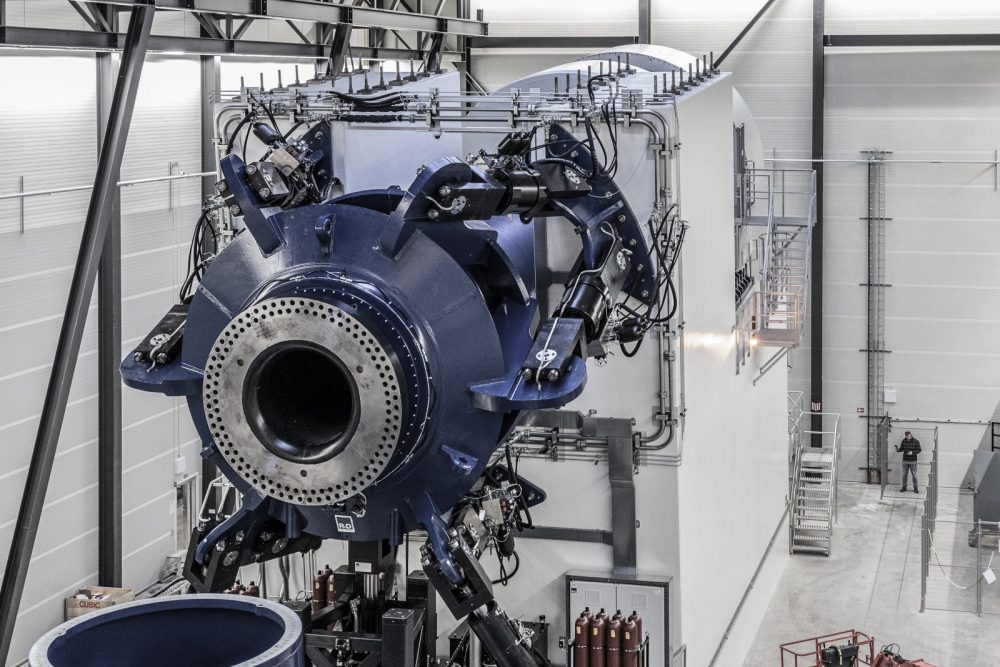

The global wind industry will test the future generations of super wind turbines at LORC in Denmark. The Danish company R&D Test Systems is designing and building the wind industry’s largest and most advanced test bench, the HALT XL.

'The world’s leading wind turbine manufacturers rely on Danish engineering skills when developing and testing future generations’ largest offshore wind turbines.

In the last half of a year, 25-30 engineers from the Danish company R&D Test Systems have calculated and designed on a regular mammoth of a test bench, which is now being built at LORC in Denmark.

The HALT XL will from January 2021 test the next generation of prototypes of the world’s largest offshore wind turbines to make sure that the enormous energy giant can withstand the scenarios out on the ocean. This requires a test bench out of the ordinary.

“We have developed large test benches before, including some of the largest in the world”, Peter Kattai Ulrikkeholm, CEO at R&D Test Systems says:

“However, this test bench is so enormous that the size in itself holds some entirely new engineering challenges. We use the entire palette of engineering skills and our many years of experience within the field to design it”, he says.

Previously, R&D Test Systems has developed and build test benches for LORC, including some of the largest in the world. Therefore, it has been the natural choice for us to seek competences, know-how, and especially the innovative approach, which R&D Test Systems can provide.

The wind turbines are growing

When the HALT XL test bench is installed in January 2021, it breaks several records.

The motor in HALT XL generates 25 MW and is 15 meters in diameter. That is three meters longer than a regular urban bus. The test bench is placed on a 30 meters long concrete block and delivers a dynamic bending moment of 85 MNm. It corresponds to the pulling power you get if you hang a car at the end of a six-kilometer-long fishing pole.

All that force will be used to exhaust the prototypes by the world’s largest wind turbines through extensive functional, structural, and electrical tests.

“The wind turbine manufactures need to have certainty that their prototypes can do what they have to,” Torben Lorenzen from LORC says.

“That certainty is only obtained when there is absolute trust in the tests they are running. Previously, R&D Test Systems has developed and build test benches for LORC, including some of the largest in the world. Therefore, it has been the natural choice for us to seek competences, know-how, and especially the innovative approach, which R&D Test Systems can provide”, Torben Lorenzen says.

A huge responsibility

The HALT XL has already been reserved by a manufacturer who wants to test prototypes for offshore wind turbines to wind farms that will provide even more green energy from 2025.

“The prototypes the test bench will work on represent several years of research and development. Fundamentally, our job is to stress that exact design as much as possible. We need to design a test bench that will expose the prototype to 20 years of the elements in just 6-8 months. That will provide the wind turbine manufacturers with a crucial insight in how their new technology reacts”, Peter Kattai Ulrikkeholm says:

“We are proud of the trust that some of the largest players in the green transition have in us, our handling of a task of this caliber, and that we can contribute to giving the manufacturers crucial knowledge of the final design,” Peter Kattai Ulrikkeholm says.

Project stats

Facts

R&D Test Systems has since 2005 established themselves as specialists in the design and development of large-scale system deliveries of test benches, and R&D Test Systems has delivered multiple test benches for LORC for use in the wind industry. R&D Test Systems has, the last few years, experienced strong organic growth, and the division has today about 75-80 engineers working full time with the development of testing equipment.