Insights

The R&D Rain Erosion Tester as a turnkey container solution

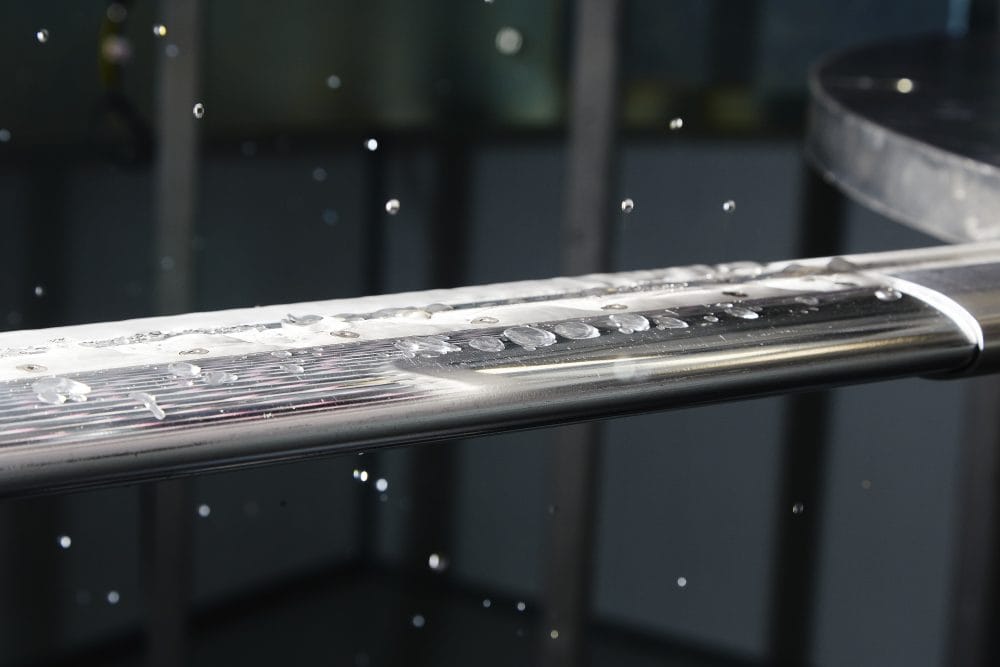

At the parking lot at R&D, Rain Erosion Testers are being built as complete container solutions, ready for running-in and use at the customer's site.

There has been a great demand for the solution since R&D sold the first Rain Erosion Testers four years ago. With the Rain Erosion Tester, wind turbine manufacturers can test erosion on the front edges of the blades. Resistance to erosion is important since it can lead to peeling of the blade surface resulting in aerodynamic inefficiency and a potentially large power loss.

Complete container solution

”Normally, the customer needs to provide a room which can house the Rain Erosion Tester,” Peter Kattai Ulrikkeholm says, Business Unit Director at R&D Test Systems. “Since we are dealing with a machine which runs extremely fast, there are certain demands to the design, including ventilation, drain, etc.”

Therefore, R&D now offers a complete product for the customer, where the Rain Erosion Tester is delivered in a 20-foot container. It is ready for use after the running-in at the customer's site. The container solution allows the customer to easily move the Rain Erosion Tester to other locations if they need to.

Complicated tests

The testing of rain erosion is very complex, and the issue is difficult to test because it is such a quick process. It has a top speed of about 180m/sec. “Therefore, the development process has required many tests in practice,” Peter Kattai Ulrikkeholm says. “In this field, you cannot calculate your way to the result based solely on theory – yet it requires a strong theoretical foundation to reach the right decision.”

Reliability and repeatability

Manufacturers have optimal erosion test capabilities such as the ability to test different coatings for the leading edges of the blades and the corresponding durability in the development of new wings. With this machine, manufacturers can ensure that the tests are as realistic as possible.

An important parameter in this process is reliability and especially the repeatability has been crucial to several customers when choosing this test solution from R&D.

With the container solution, the customer avoids the problems which can occur when setting up a room for the tester. “Several customers have already chosen our solution,” Peter Kattai Ulrikkeholm says. “Throughout a period, we have been considering how we could make it easier for the customer. The feedback shows that this solution perfectly suits many customers’ needs.”

How can we help you?