Sea fastening

If you want to cost optimise your project, you must make the right decision from the beginning.

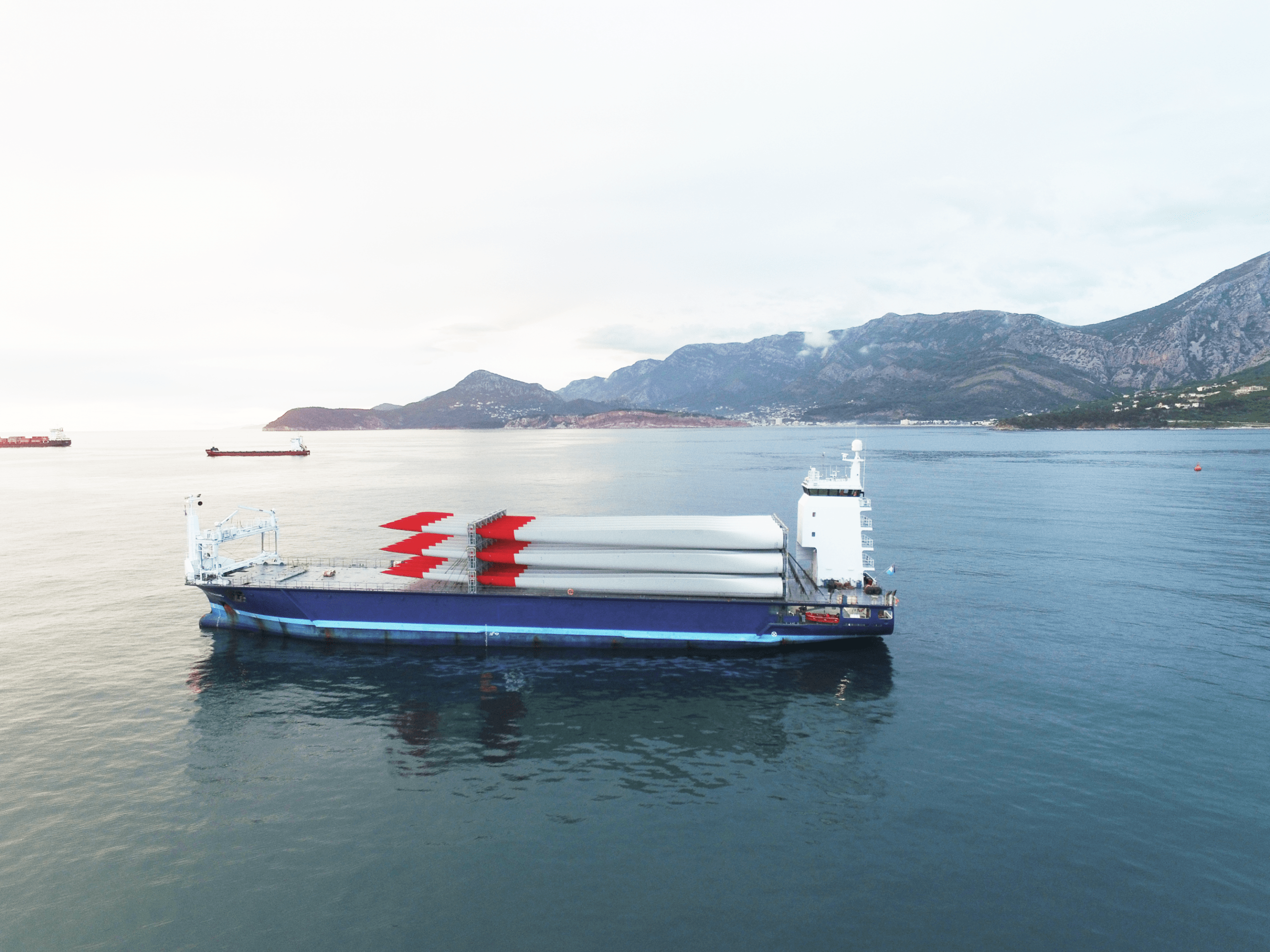

Over the last three decades, the technology within the wind industry has developed significantly in progress with wind turbines increasing in size. As wind turbines increase in size and complexity, transport solutions are pushed to the limit in regards to both fastening the components and in a number of components for each trip. Although maximizing the amount of components reduces the number of trips and thereof the overall costs of offshore wind farm installation, it is relevant to determine other ways of optimizing transport.

When designing equipment for transportation, engineering costs are an almost insignificant part of the total cost for that process. However, the early engineering phase is crucial in terms of optimizing the transport solution. We often experience that when the design phase is undervalued, the cost for manufacturing and operations increases. Although the engineering costs are often insignificant compared to the transport costs themselves, it lays the foundation for manufacturing and operation. With the right engineers and specialists, the efficiency in your transport solutions can be improved and costs significantly reduced.

How can R&D support your project?

R&D’s blade transport systems recognize that no two blades are the same. Different dimensions, weights and materials mean that standard products do not necessarily provide the most efficient use of your shipping and storage space. Here are six matters that R&D can help you with, as your external consultant.