Insights

R&D receives international acclaim for innovative test system

R&D's Rain Erosion Tester is used by some of the world’s leading companies within the wind industry and has earned international acclaim for its reliability and documented repeatability.

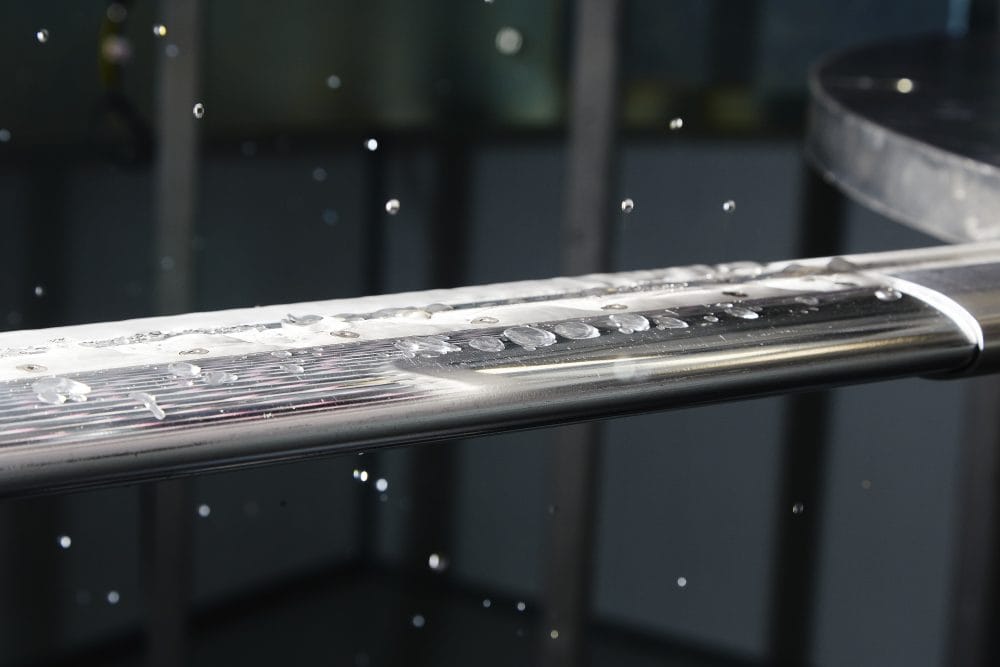

Over the last couple of years, R&D has focused on the development of a Rain Erosion Tester, which supports the wind industry in extending the longevity of wind turbine blades. The result is a test system with calibration procedures and a proven level of repeatability, which is internationally acclaimed and used by some of the world’s leading companies within the wind industry.

R&D's experience and competences within test systems have been a decisive factor in the development of the Rain Erosion Tester. The test system is designed to realistically simulate the effects of rain erosion endured on the leading edges of wind turbine rotor blades.

International acclaim

"It has been beneficial for the outcome to have all competences internally. The close correlation between mechanics, software, automation and electronics ensure a wider perspective on the development process and a more unified test system," Mads Erik Mathiesen says, Key Account Manager at R&D Test Systems.

R&D's Rain Erosion Tester has earned international acclaim for its reliability and documented repeatability. "So far, five companies worldwide use our test system. Among them are LM Wind Power, ORE Catapult and two leading companies within the wind industry," Mads Erik Mathiesen says and continues: "The documented repeatability and reliability were decisive factors in their decision to buy our Rain Erosion Tester."

The most reliable test method

Due to the success of the Rain Erosion Tester, R&D has intensified both resources and competences to secure a competitive product. "We want to increase customer value and offer the wind industry the most reliable test method, which is why we have invested significant resources in further development of the test system. Due to the internal expansion and the feedback from our customers, we have the qualifications to explore how to improve the system," Mads Erik Mathiesen says.

Rain Erosion Tester to the aviation industry

"We are exploring the needs for leading edge protection within the aviation industry," Mads Erik Mathiesen says. Earlier this year, R&D delivered a test rig for an aircraft engine power gearbox to Rolls-Royce. "The knowledge and experience we gained from that project can prove highly valuable to the Rain Erosion Tester's success within the aviation industry."