R&D Test Systems has installed the first Aerospace Rain Erosion Tester

R&D Test Systems has installed the first Aerospace Rain Erosion Tester

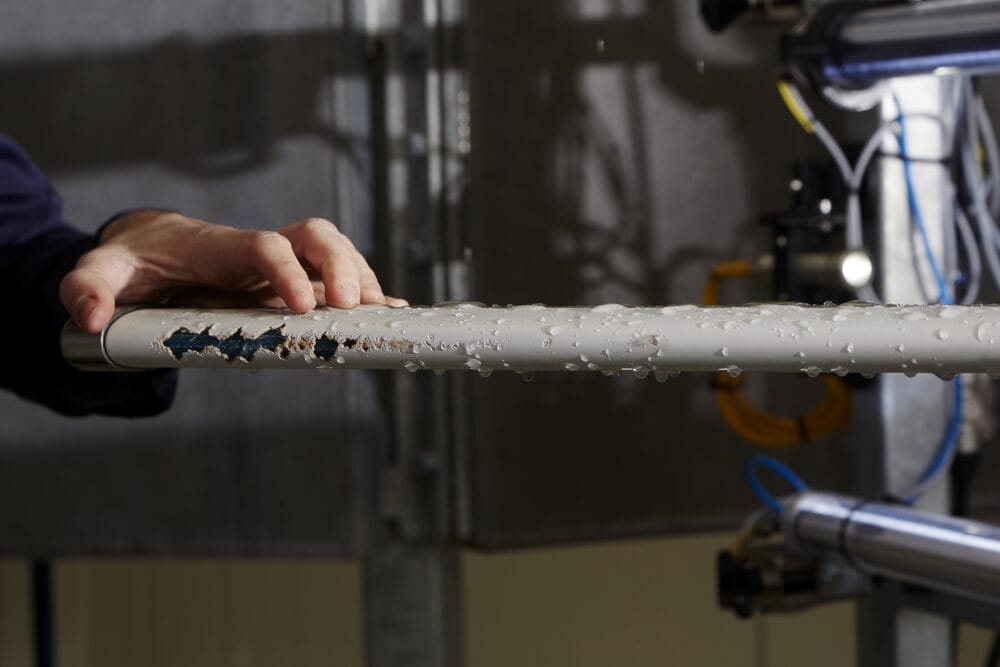

R&D Test Systems installed the first Aerospace Rain Erosion Tester for a coating company. Based on a 3-bladed helicopter principle, the test specimens are shaped like the leading edges of an airplane wing. This test setup simulates and ensures conditions very similar to real-life harsh weather and rain in an accelerated way with very high repeatability.

“With the Aerospace Rain Erosion Tester from R&D Test Systems, it is possible to make unique and faster testing of erosion on the leading edges of airplane wings. By having a rain erosion tester in-house, the company can perform more precise and frequent testing of coatings – reducing costs and time-to-market,” explains Rasmus Refshauge, Key Account Manager at R&D Test Systems.

R&D Test Systems has installed a Rain Erosion Tester at five different coating companies that supply coating to the wind and aerospace industry.

Full DNV and specification compliance

To simulate the speed of an airplane compared to a wind turbine, the test specimen maximum tip speed has been increased from 173 m/s to 224 m/s. The test system has a proven level of repeatability and complies with SAE AMS-C-83231A Aerospace Material Specification for Coatings. This test system has a proven level of repeatability and fulfills DNV's Recommended Practice (DNV-RP-0171) for the testing of rotor blade erosion protection systems.

How can we help you?