Case study

Behind the mechanical upgrade of Vestas’ test bench for wind turbine gearboxes

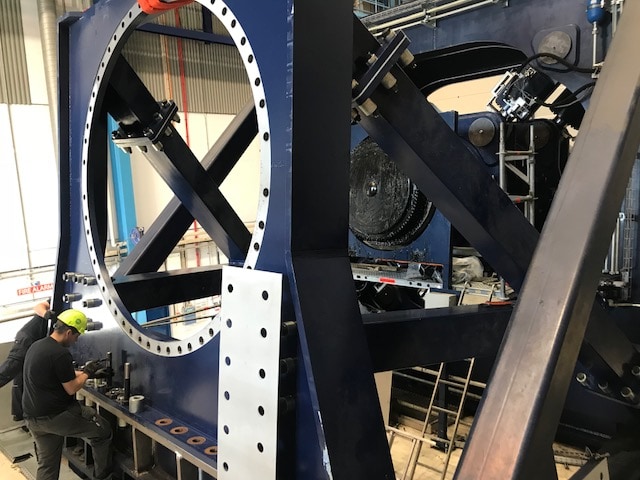

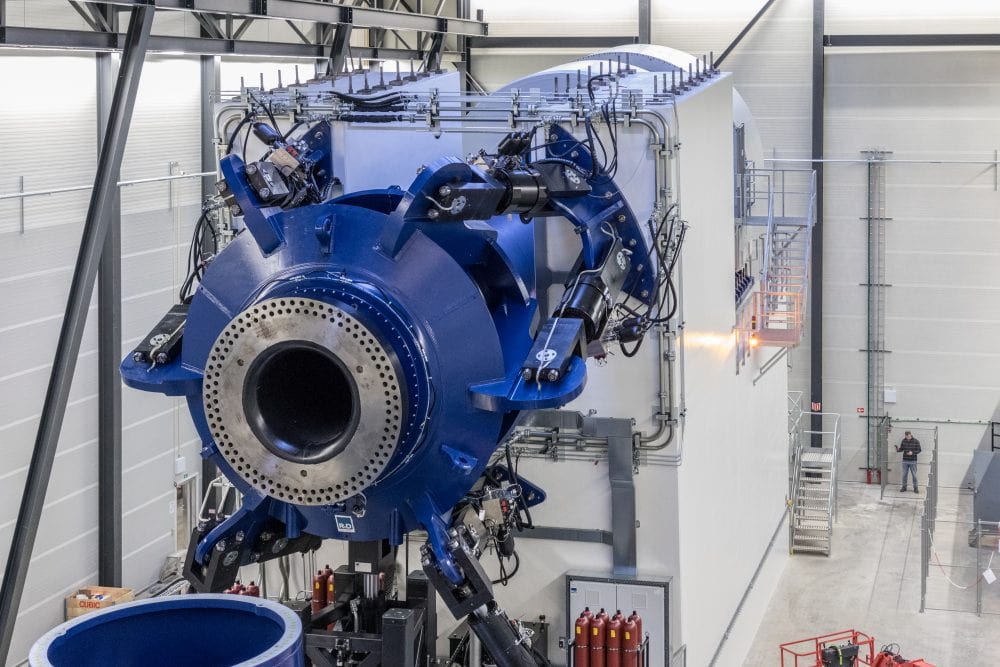

R&D Test Systems and Service & Installation have been responsible for the mechanical upgrade of Vestas' test bench for wind turbine gearboxes.

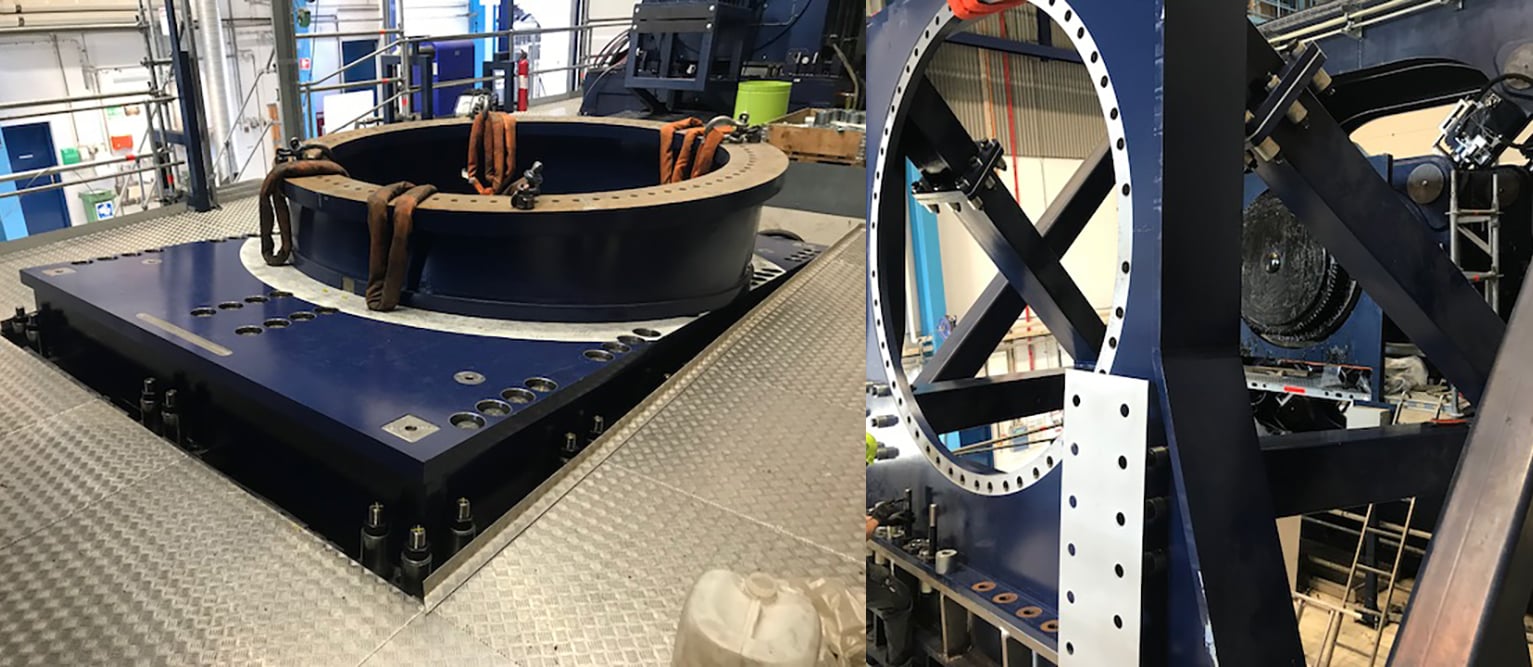

In 2011, R&D’s departments of Test Systems and Service & Installation designed and delivered a test bench for wind turbine gearboxes to Vestas. Due to the advancing technology within the area, wind turbines have evolved a lot since then. In this context, Vestas needed an upgrade of the test bench to ensure the right evaluation of the behaviour of the gearbox under different load conditions.

“R&D’s departments of Test Systems and Service & Installation developed and delivered the original test bench. Therefore, it was natural for us to involve them in the upgrade of the test bench. Due to their knowledge and understanding of the system, they have been able to provide us with the most beneficial outcome in the most efficient way,” Flemming Christensen says, Specialist at Vestas.

The upgrade of the test bench was initiated with a pre-study to ensure that the specification was consistent with the new requirements and to secure that the upgrade did not cause any overload of the existing components. To avoid any unnecessary downtime of the test bench, they were looking at a tight timetable.

Due to their knowledge and understanding of the system, they have been able to provide us with the most beneficial outcome in the most efficient way

In-house capabilities increase the flow of information

The project has been a great example of why it is beneficial to cooperate with a company who has the necessary system insight; both concerning know-how and resources.

“The flow of information is essential for the outcome of any project seeing that it can prevent the cause of delays, misunderstandings, etc. Due to our tight timetable, the flow of information between us and R&D played an essential part in the execution of the project,” Flemming Christensen says and continues:

“In that connection, it has been a significant advantage that R&D has been responsible for the entire upgrade of the test bench; from the development and assembly to installation and commissioning. The close correlation between R&D’s engineers and their assembly team has made the process more efficient”.