Case study

Polytech proves lifetime of product with Rain Erosion Tester from R&D Test Systems

Polytech proves lifetime of product with Rain Erosion Tester from R&D Test Systems

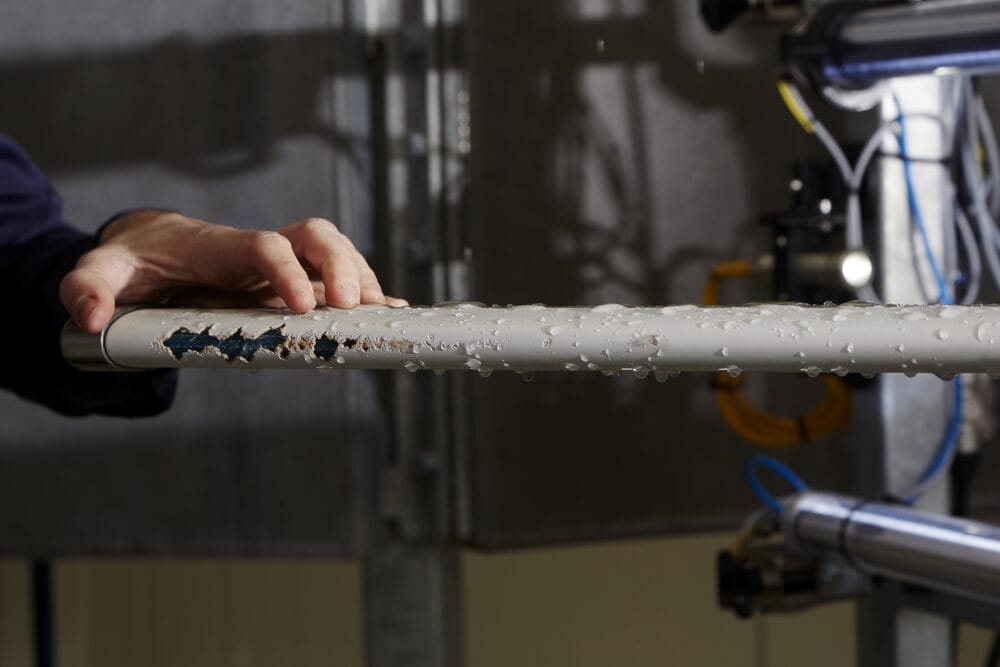

A significant and growing problem in the wind industry is the erosion on the leading edge of wind turbine blades caused by impacts from rain droplets and other particles on the blades rotating at high velocity.

The eroded blades are a problem as they can significantly reduce the turbine's performance and can lead to structural damages of the blade. And repairing wind turbine blades, especially offshore, is very costly. So, any solution that can prevent erosion has the attention of the OEMs and park owners.

"The industry has for decades tried to prevent the erosion of the blades. Today, most wind turbine blades have some sort of leading edge protection solution applied, but there is a huge difference in their performance and durability," explains Michael Drachmann Haag, Materials Specialist at Polytech.

New test setup

In 2018, Polytech invested in a new rain erosion tester as the industry moved towards more standardized testing forms. Polytech decided on the Rain Erosion Tester from R&D Test Systems, which was already at the time the preferred test equipment of the OEMs. The rain erosion tester was delivered and installed in the spring of 2019.

"We believe in a holistic approach when developing solutions for our partners in the wind industry. That is why we have invested significant resources and developed in-house capabilities to test materials and products at our accredited testing facility in Bramming," explains Michael Drachmann Haag.

A validated lifetime of product

With the new test system, Polytech could prove the lifetime performance and durability of their existing leading edge protection product 'ELLE,' short for 'Everlasting Leading Edge.' ELLE™ consists of pre-cast sections of robust yet soft and flexible polyurethane shells. It is installed on more than 20,000 turbines worldwide.

Polytech followed the DNV-RP-0573 to forecast the durability of ELLE™. As part of this process, the product has gone through an extensive rain erosion testing following the DNV-RP-0171. ELLE™ samples were exposed to thousands of hours of continuous rain erosion tests, followed by 25 weeks of aging cycles (salt spray and low temperatures), then another several hundreds of hours of rain erosion tests.

Polytech’s rain erosion tester from R&D Test Systems forms the backbone of Polytech’s testing capabilities for leading edge protection (LEP) materials. Combined with various in-house environmental tests, Polytech could accurately forecast their LEP's lifetime. Using the rain erosion tester, Polytech could prove that the ELLE™ softshell is of the best possible quality and the most durable material on the market to protect blades from erosion.

Very high utility of the test hours

With good planning and help from the RET automation system, Polytech can achieve a very impressive utilization of 82% of the test machine. They can do this as the RET system allows for test execution with automatic image documentation while the alarm system monitors the machine. Furthermore, the machine has integrated remote access and SMS service, which enables the operator to control the system from anywhere, allowing the machine to also run during weekends and holidays.

Since the beginning, Polytech has requested special add-ons for the machine, which R&D Test Systems has worked continuously to develop. The cooperation has resulted in a close partnership regarding the operation and further development of the machine.

Currently, Polytech and R&D Test Systems are working together on implementing a new camera solution, which will improve the pictures of the test subjects when the machine runs. By having even better quality pictures, it will be easier to evaluate the erosion patterns on the test subjects and the customers can also benefit from these improved pictures in the test reports. This is essential to Polytech as they not only test their own products but also act as an accredited test institute and create test reports with pictures for other leading edge protection solutions.

"We are very happy with our collaboration with Polytech considering further development and upgrades to the Rain Erosion Tester. It is important to us that we have a partnership with our customers, and we strive always to improve our service and support," concludes Niels Pedersen, Key Account Manager at R&D Test Systems.

Photo credit: Jakob Ilsted Bech /DTU Wind & Energy Systems

We believe in a holistic approach when developing solutions for our partners in the wind industry. That is why we have invested significant resources and developed in-house capabilities to test materials and products at our accredited testing facility in Bramming

Polytech:

Polytech is a global partner in the wind industry with facilities all over the world. The company provides holistic solutions within lightning protection, leading edge protection, blade monitoring and optimization, transportation, and wind turbine performance and structural components.

The industry preferred Rain Erosion Tester

R&D Test Systems has during the past decade delivered more than 14 machines with the specific purpose of developing and evaluating rain erosion on the lead edge.

The Rain Erosion Tester from R&D Test Systems has become the preferred test method within the wind industry since it offers a proven level of repeatability and fulfils DNV’s Recommended practice (DNV-RP-0171) for the testing of rotor blade erosion protection systems. The machine is based on a 3-bladed helicopter principle with test specimens shaped like the leading edges of a standard wind turbine blade.

How can we help you?