Insights

Installation of one of the world’s largest test benches

R&D is currently building one the world's largest test benches to LORC. The installation of several elements has already been completed and R&D expects that the test bench is ready for use by the end of this year.

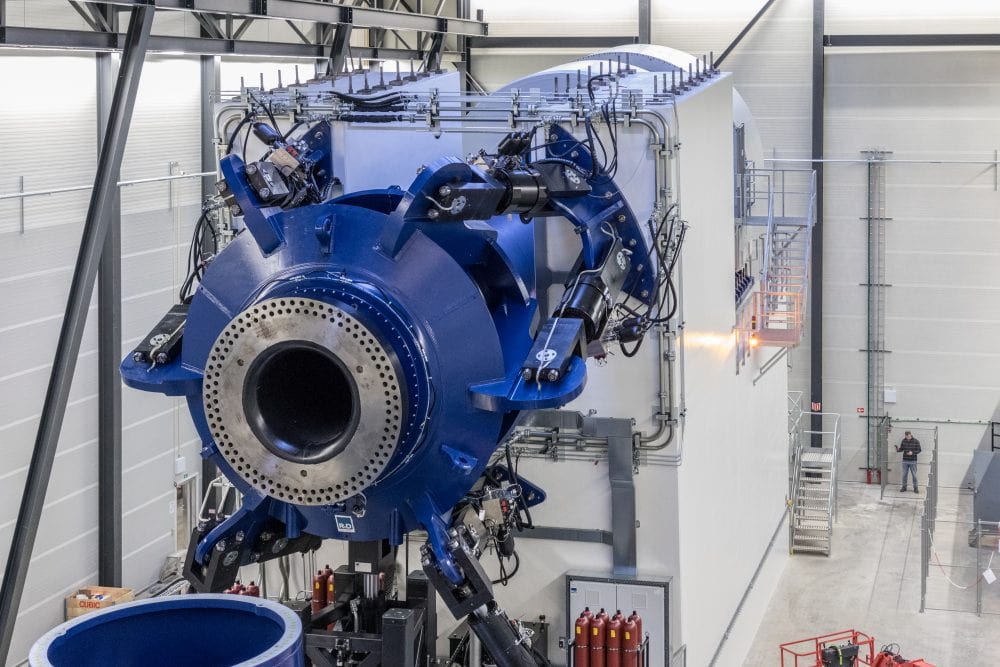

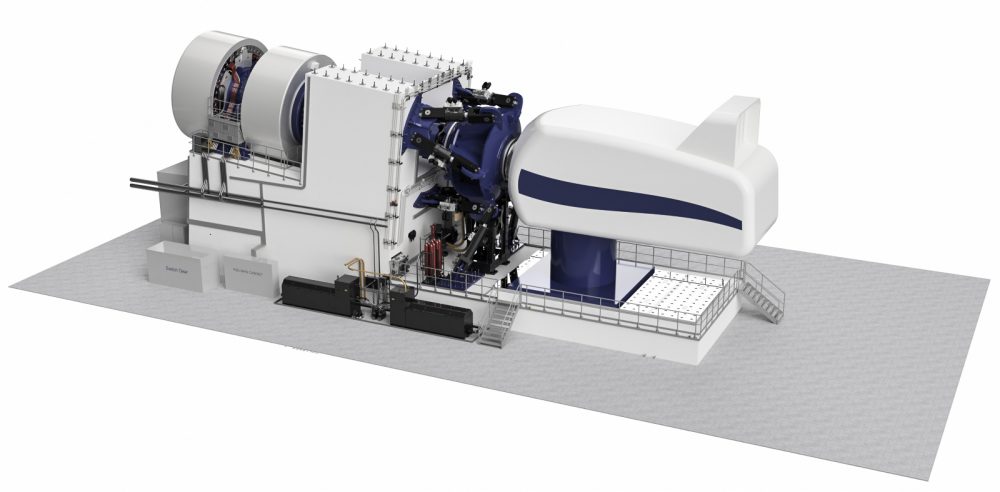

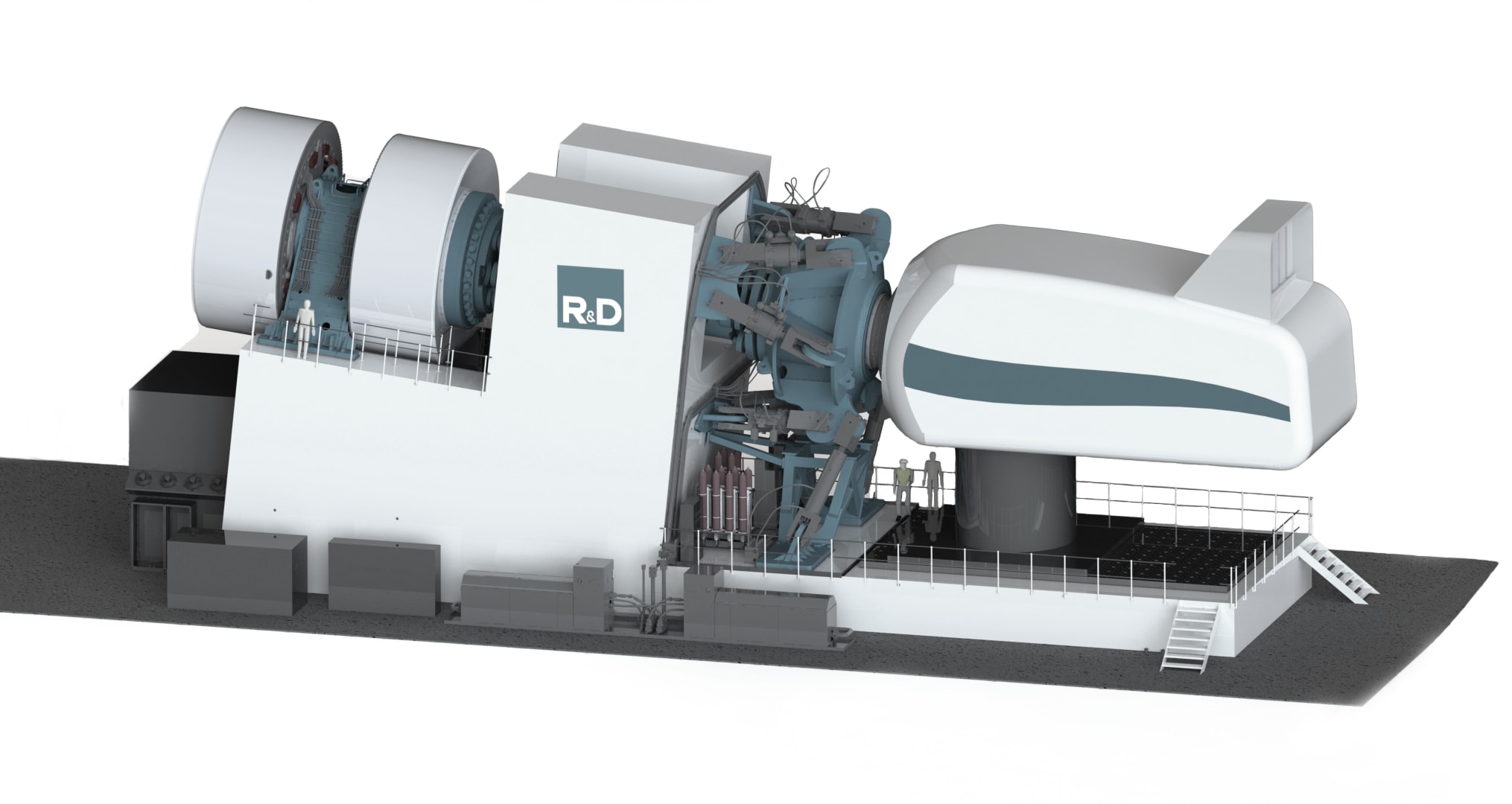

The test bench is a wind load simulator for Highly Accelerated Life-cycle Testing (HALT) of wind turbines. The hydraulic Test Load Unit operates as a wind simulator and can replicate the reactions of the wind on the main axle of the test subject using three forces, two bending moments and one torque level.

The Test Load Unit can apply a bending moment of up to 25MNm to the test subject in addition to the drive motor system and drivetrain, which can add a torque of 14.5MNm to the test subject. Thus, the test bench is a large mechanical, hydraulic and electrical wind tunnel for accelerated fatigue tests.

Successful installation

The project proceeds as specified in the project plan. The foundation for the test bench is built as a reinforced concrete foundation with a volume of approximately 1,500 m3. It consists of two 14 meter high pylons, a 6x11 meter tooling area for fastening the test nacelle and walls for the drive motor system.

The drive motors and the associated converter system have been successfully installed, and commissioning will be completed by the end of August.

The installation of the hydraulic wind load system as well as the production of the complex hexapod steel structure are in progress. These elements will transfer the loads from the test bench to the test nacelle.

Ready for use by the end of this year

The first initiatives regarding the test bench started in spring 2015. Since then, R&D has been working intensively to construct and install the test bench. The on-site work started in June 2016, and the test bench will be ready for use by the end of this year.