Case study

American university seeks R&D’s expertise

R&D's status as one of the world’s leading companies within the development of test systems for the wind industry led the Americans to buy consultancy support from R&D.

"Over the past several years, America has been working to use less dirty energy, use more clean energy and waste less energy throughout our economy,” Barack Obama said in his remarks on the Clean Power Plan on the 3rd of August, 2015.

Several times, the President of the United States, Barack Obama, has announced that America needs to convert to green energy. Just as the leaders in Europe, Obama wishes to reduce the consumption of fossil fuels and the emission of carbon dioxide into the atmosphere. Even though the Americans historically have not been too keen to abandon their expensive and non-green energy habits, there might be a movement in the American cleantech sector.

R&D was at the top of our list of companies which we would like to collaborate with. They have great experience in this field. R&D is very customer-oriented and flexible and has a great knowledge of test equipment.

Clemson University has been pursuing the best collaborators

At Clemson University in South Carolina, the first American test centre for wind turbines will soon be ready. One of the suppliers of the test equipment is R&D. Kenth Skipper-Mortensen is a mechanical engineer at R&D. He is the project manager of the assignment which consists of developing and delivering equipment for calibration for a test bench. Kenth Skipper-Mortensen is not surprised that the Americans have sought help in Aarhus.

”When it comes to green energy and wind energy, Denmark is one of the world’s leading countries due to Vestas and Siemens Wind Power. We are some of the most specialised in the field of testing the turbines. We have much experience, which we can use, and we have very competitive prices,” Kenth Skipper-Mortensen explains.

Andrei Mander is a systems engineer and the director of operations on test and wind energy at Clemson University. He does not hide the fact that Clemson has been pursuing the best collaborators; ”R&D was at the top of our list of companies which we would like to collaborate with. They have great experience in this field. R&D is very customer-oriented and flexible and has great knowledge of test equipment. And they comply with budgets and deadlines if you were to mention some of the things they excel at,” Andrei Mander says.

First test centre in the US

The new American test centre will primarily be used to perform lifetime tests of the large offshore wind turbines. The test centre will be the first of its kind in the United States. In Denmark, there are several test rigs. Vestas has different test rigs for various sizes of offshore wind turbines and soon LORC (the national centre for the testing of wind turbines) will have their first test rig ready for testing offshore wind turbines.

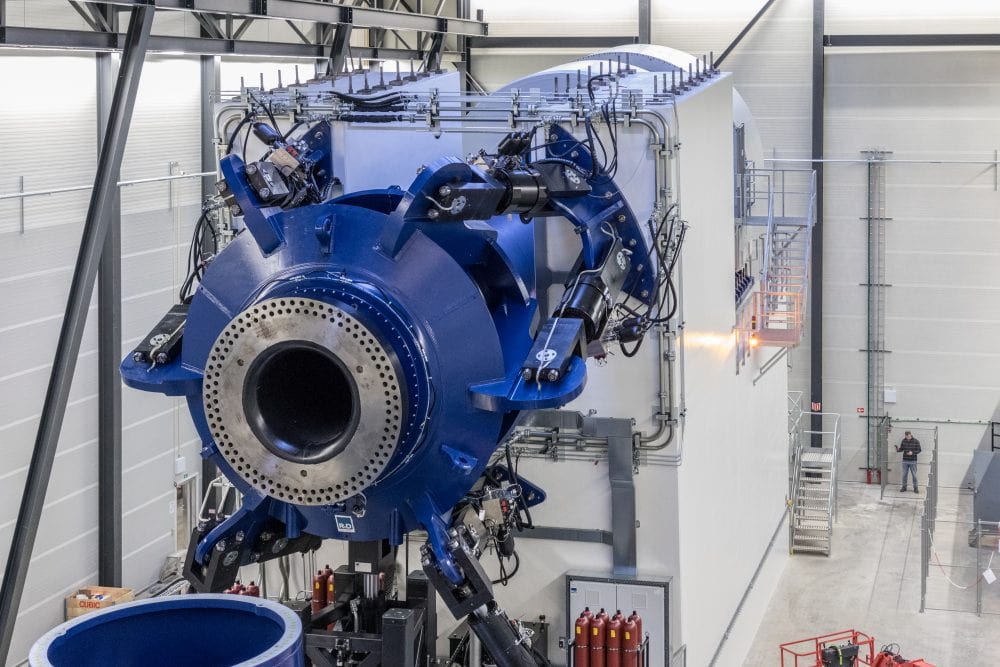

The lifetime tests, which the Americans wish to perform on the large turbines, demand a robust and a very accurate calibration system. The new calibration system to Clemson University was developed by R&D and produced in Denmark before being transported by container to the United States.

After a close examination of tenders from various manufacturers in the United States, it turned out to be a cheaper solution to produce the system in Denmark and ship it to the United States afterwards. The collaboration has purely been long distance, as neither the project manager nor the man behind the project, Morten Storm Pedersen, owner of R&D, went across the Atlantic to visit the university in South Carolina.

”Beside the purely technical challenge of creating the equipment, it has also been a challenge to deliver the product to the other side of the Atlantic Ocean. Suddenly communications, culture and logistics are important in a different way than usually in the collaboration with the customer, as phone or emails were our communication channels,” Kenth Skipper-Mortensen says.

Moreover, this does not seem to be the last project which R&D solves in the United States. Due to the collaboration with Clemson University, R&D can submit tenders for future projects which would normally only be distributed among the university’s internal collaborators in the United States.

How can we help you?