Test Systems

Rain Erosion Tester

Rain Erosion Tester

Improve the longevity

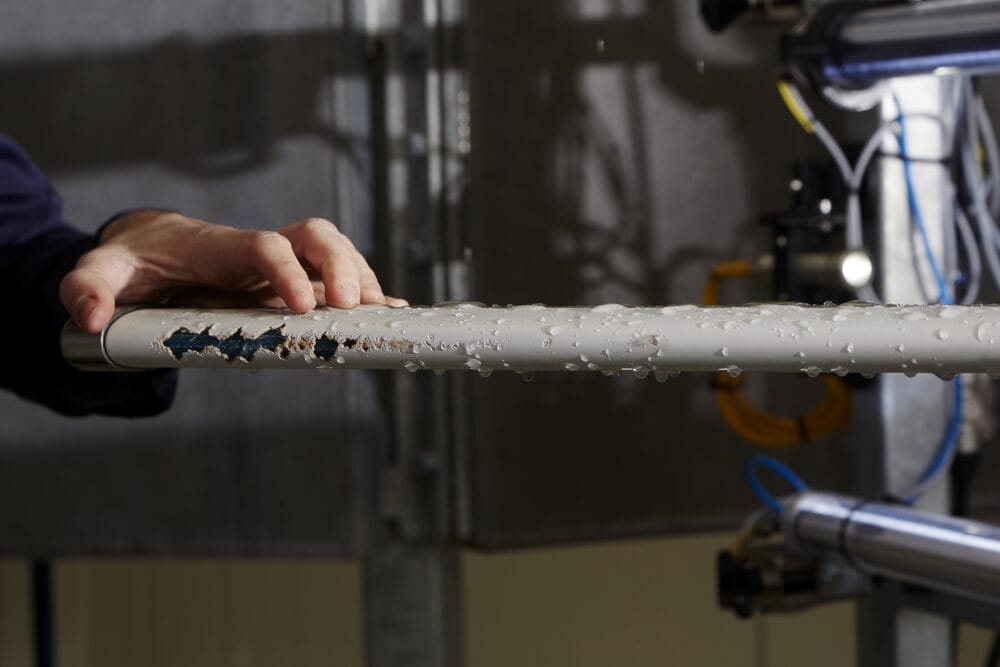

Erosion on leading edges is an increasing problem within the wind industry due to harsh weather conditions or increased rotor speeds, and airplanes experience similar erosion on their wing tips due to rain at high speed.

Currently, 16 Rain Erosion Testers have been sold worldwide to coating companies and test centers, including Hempel, Polytech, ORE Catapult, LM Wind Power, and Technical University of Denmark - DTU.

The Rain Erosion Tester from R&D Test Systems offers the most precise and standardized way of testing new products and verifying batches of leading-edge protection systems. The test system is based on a 3-bladed helicopter principle with test specimens shaped like the leading edges tip of a standard wind turbine blade or aeroplane wing. This test setup ensures conditions very similar to real-life harsh weather in an accelerated way.

Benefits

- Comprehensive turnkey test system delivered, including test chamber or for building integration

- Proven level of repeatability and reliability

- User-friendly operator interface

- High uptime since test can be conducted automatically after initial running-in

- Automatic erosion documentation and test report

- Test specimen design that allows testing of various surfaces on materials like fiberglass and aluminum

- Full-automatic operation

- CE marking

Standards

The Rain Erosion Tester complies with ASTM G73-10 Standard Test Method for Liquid Impingement Erosion Using Rotating Apparatus, and has a proven level of repeatability and fulfils DNV’s Recommended Practice (DNV-RP-0171) for the testing of rotor blade erosion protection systems.

Furthermore, for aerospace testing, the test system complies with SAE AMS-C-83231A Aerospace Material Specification for Coatings, Polyurethane, Rain Erosion Resistant for Exterior Aircraft and Missile Plastic Parts.

Adjustable test parameters

Rain Erosion Tester

Our services

R&D Test Systems offers a turnkey solution that includes the rain system, a rotor with test specimen holders, drainage, ventilation, and control system delivered in a housing of 20-foot containers.

System safety is an important parameter because it ensures safe operation during tests at extreme rotational velocities. System safety is guaranteed both by R&D Test Systems and by external machine safety specialists.

We offer rain erosion testing for the development of features and technologies at our own rain erosion tester in Hinnerup, Denmark. The machine is equipped with a dual droplet system and can run tests at both wind and aerospace speeds.

If you are interested in rain erosion testing, you are welcome to stop by and see the machine.

Contact Key Account Manager Niels Pedersen for more information at npe@rdas.dk or +45 63 25 20 51.

How can we help you?

For further information about the Rain Erosion Tester, please contact us